18/10/2025 – The double pressure welding (DD) process for non-ferrous metals

Efficient and high-strength joints

In modern manufacturing technology, the joining of non-ferrous metals such as aluminum, copper, and other alloys is becoming increasingly important. Especially in industries like electrical engineering, automotive, and machinery, reliable and high-strength welds are in demand.

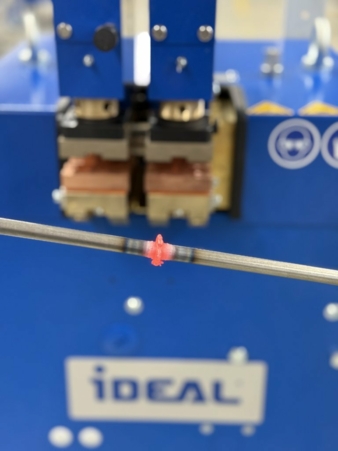

The DD process is a specialized welding technique that can be implemented on certain machines, such as models “DSH 130” and new “DSH 250”, equipped with the NE configuration. © Ideal-Werk

The double pressure welding (DD) process represents a significant advancement in welding technology for non-ferrous metals. © Ideal-Werk