26/06/2024 – New developments from Kurre Systems

Changing the pintle during operation

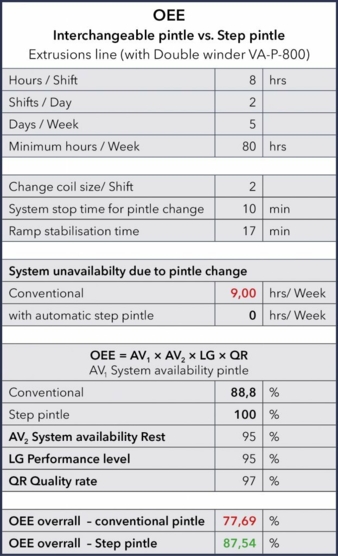

Replacing pintles for holding and winding different spools is time-consuming. In addition to the downtime, this also increases the scrap rate. What if it were possible to change the pintle during operation - without any set-up times or loss of material? Kurre Systems asked itself the very same question.