24/06/2024 – Cable manufacturing / simulation

Cable analysis using 3D modeling and simulation technology

NKT in Sweden uses numerical modeling to investigate electromagnetic fields and calculate armor losses in 3D cable designs. The modeling results were validated with experimental measurements in order to be able to carry out design analyses with the aid of simulations.

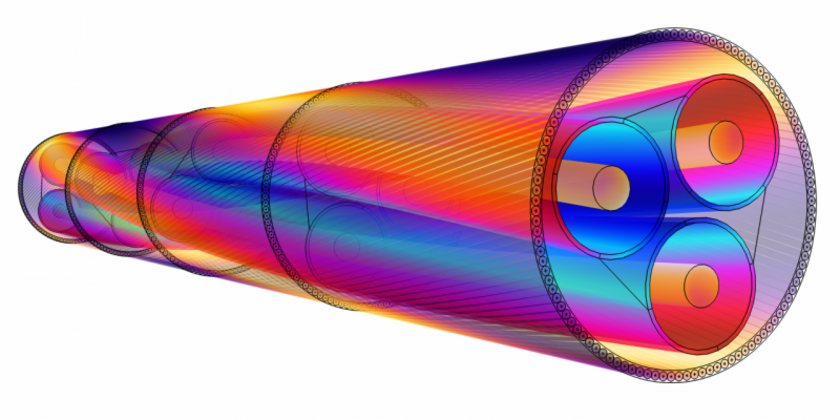

Fig. 2: The geometry of the 3D magnetic flux in the air gap between the conductors in the armored cable model. © Comsol

Fig. 2: The geometry of the 3D magnetic flux in the air gap between the conductors in the armored cable model. © Comsol

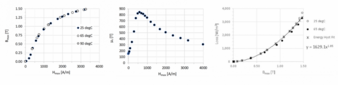

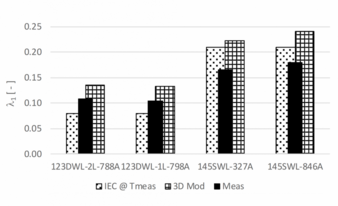

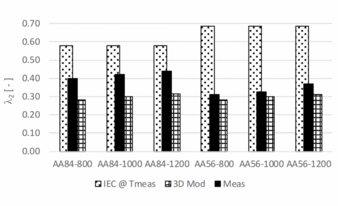

Fig. 4: Validated results, clockwise from top left: IEC, measured and modeled losses in five cable designs; measured and modeled shield currents; IEC, measured and modeled values of ?1; and IEC, measured and modeled values of ?2. © Comsol

Fig. 4: Validated results, clockwise from top left: IEC, measured and modeled losses in five cable designs; measured and modeled shield currents; IEC, measured and modeled values of ?1; and IEC, measured and modeled values of ?2. © Comsol