25/12/2025 – Videx Multiple-Extrusion machine from Coil or Bars

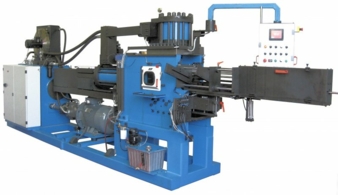

Multiple-extrusion machine from coil or bars

Videx is combining its straighten, cut and chamfer machine with its bar-end Extrusion machines, forming a complete line, from coil to a finished product.

The straighten cut and chamfer machines pull wire from coil, straighten it, cut to length and chamfer one end or both ends. The cut and chamfered parts are directly transferred to a magazine, from which they are automatically fed to an extrusion machine. The Extrusion Machine (VEM) reduces the diameter of bars from major diameter to pitch diameter (for threads) or to any diameter for other applications like drill bits.

Each extrusion process is limited to 17%-20% volume wise, and in case the parts need to be chamfered more, then the parts have to go through a multiple extrusion process.

Long extrusions is optional to almost any length by stepped extrusion. In this case, the part is gripped, the machine extrudes a preset length and then the grippers open and the part is automatically forwarded, to be gripped again, for completion of the extrusion. When the parts have to be threaded at a second process, they are extruded to pitch diameter, enabling thread rolling in an automatic process, without having to peel or turn the bar ends.

The VEM line handles cold drawn, hot-rolled (scaled) and ribbed bars and is available as either independent machines or part of a line. Hand-Feed machines are also available for long bars, headed parts and bent shapes.

When extruding hot-rolled bars, the extrusion die breaks the scale and draws the bars to the pitch diameter, leaving a clean face that results in good thread quality. The VEM series are equipped with automatic oiling that applies extrusion oil around the bars before the extrusion starts. Each model in the VEM line covers a wide diameter range, say Ø 5mm-25mm or Ø 12mm-40mm. The extrusion stroke adjustment is quick and easy.

The VEM models are also available with higher tonnage ratings for upsetting and heading. The machines can be supplied with 1 or 2 stations with either open dies or closed dies and heading tonnage up to 400 tons.

wire 2026, hall 16 booth E 26

Videx Machine Engineering Ltd.

20, Shabazi Street

5623107 Yahud/Israel

Tel.: +972 3 35364801

videx@videx.co.il