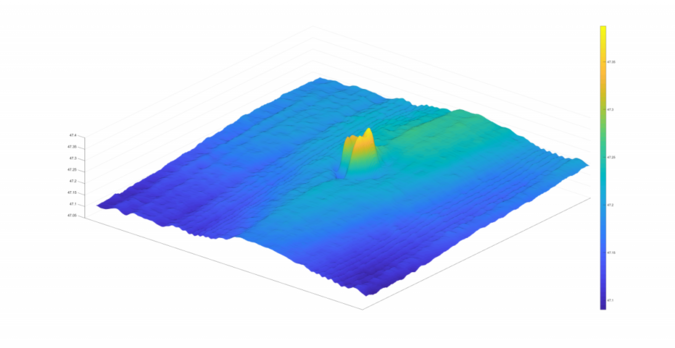

11/03/2021 – 3D view of the cable's surface

AI enhances detection of surface anomalies

Maillefer Extrusion Oy is very excited to be at the cutting edge of smart manufacturing technologies, especially when they take the shape of working solutions. One such realization is their “Topography Scanner”, a system for state-of-the-art analysis of measurement data.

Image of a scorch particle detected by the Topography Scanner. Height 100?m, width 150?m, length 200?m. © Maillefer

By coupling innovative AI technology with performant surface laser sensing, Maillefer brings enhanced quality control into the production environment. © Maillefer