11/03/2021 – 3D view of the cable's surface

AI enhances detection of surface anomalies

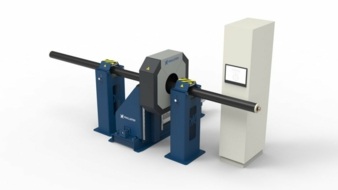

Maillefer Extrusion Oy is very excited to be at the cutting edge of smart manufacturing technologies, especially when they take the shape of working solutions. One such realization is their “Topography Scanner”, a system for state-of-the-art analysis of measurement data.

Artificial Intelligence (AI) lies at its core. It consists of a sophisticated self-learning neural network that parses through over five million data points per second in search of anomalies. Contrary to visual inspection, the neural network has enhanced detection capabilities that are thorough and accurate.

Their recently introduced “Topography Scanner” is built around multiple laser sensors for scanning the entire circumference of the produced cable. The resulting data provides a high-resolution surface height projection, a 3D topographical map of the cable surface. A 2D cross-sectional profile shown in real-time aids operators in identifying quality issues as cable moves through the scanner. An enhanced 3D view of the cable's surface is also visible, as the cross-sections are accumulated over time. The key metrics are calculated and saved into our data logging system for future reference.

A properly developed neural network

Their scanner's essential features are considerably enhanced through the use of AI and a properly taught neural network. Indeed, a neural network first requires training in order to function reliably. We first introduce the vast training data library compiled from cable samples manufactured on our Pilot Vertical Line and from ones coming from our customers. The teaching continues by purposely creating defects on cable surfaces, as the system progressively learns to identify defects.

Maillefer evaluated several different convolutional neural networks (CNN) during the development phase in order to find a network structure that best suits our application. This type of neural network is well suited for detecting shapes and features in data. In the world of neural networks there is a balance between required training data, computational power and network accuracy. Fortunately for us, we generate an optimum amount of training data for the CNN to run well on the specialized hardware that is designed for neural networks requiring high performance. The two favorable factors lead to a very high accuracy.

In tandem with the operator

All the topographic data is split to smaller samples and then sent to the AI system for inferencing. Each sample is then classify according to predefined classes. When the AI detects something that is classified as a defect, a warning message is sent to the operator together with a picture of the defect. The image allows the operator to see the defect's width, length and height or depth. The system also shows the defect's class and associated level of certainty.

This is especially useful in teaching the system to reduce the amount of false positives. Advanced users are able to classify each detection as a true or false positive. During and after the commissioning, it is then possible to fine-tune the AI system by supplementing it with the additional classifications coming from a customer’s production.

Smart identification

With their AI system, it is possible to literally train the system to notice certain things or not. One such example of a customer specific issue, are the mark lines deliberately made to indicate the orientation of cable core. In another example, we teach the system to ignore water droplets on the cable surface after cooling, or ignore other marks originating from byproducts.

An added advantage in using a CNN based AI system is that these new methods make it possible to improve the resolution of the Topography Scanner as a whole. Even a small anomaly that is nearly the same size as the sensor's own signal noise becomes possible to identify. This is because AI treats noise from the sensor itself as background noise and so can recognize the minute deviations that reveal a defect.

Enhanced control with quality assurance

By coupling innovative AI technology with performant surface laser sensing, Maillefer brings enhanced quality control into the production environment. The thoroughness and accuracy gained over visual inspection methods offers added assurance that the product customer deliver meets the expected quality standards.

Maillefer Extrusion Oy

Ensimmäinen savu, P.O. Box 176

01511 Vantaa/Finland

Contact person is Pirita Olli

Tel.: +358 9 88665-600

pirita.olli@maillefer.net