07/09/2023 – Spring manufacturing / Grinding

A grinding machine for each spring to be ground

OMD Officina Meccanica Domaso S.p.A., an international company known for its experience and competence in the field of machinery for springs, manufactures and develops a full range of grinding machines for any production requirement.

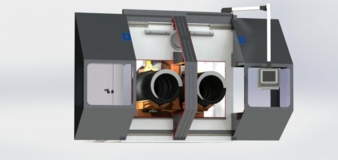

M2: This machine is provided for simultaneous grinding of both ends of cylindrical and conical compression springs. © OMD