02/07/2025 – Materials

High-temperature alloy for aerospace and automotive

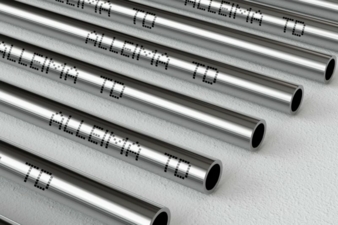

Alleima is proud to announce, “Alleima TD”, an innovative solution for the heat treatment industry with a need for reliable high temperature materials. The product ensures consistent performance for mineral insulated cable (MIC), measurements, and heating cables, even at extreme temperatures up to 1,250°C.

Industries with focus on productions of automotives, aluminium, gas turbines, and aerospace engines, are known for its harsh environments that puts high demand on surrounding materials in the production. “Alleima TD” is a response to the increasing demand from these kind of industries as they need new products with high precision, reliability, and safety requirements for temperature, control, and measurement engineering.

With over 160-years of Swedish steelmaking heritage, Alleima, a leading manufacturer of high value-added products in advanced stainless steels and special alloys, can now provide a high-temperature alloy with excellent corrosion resistance, and strength for advanced MIC protection. “Alleima TD” ensures consistent performance in elevated temperatures minimizing corrosion and contamination of the cable insulation.

“Together with ISOMIL a leading manufacturer of mineral-insulated cables in Germany, we engaged in a mutual product development in September 2021. The partnership resulted in a firm order for “Alleima TD” tubing, with successful delivery in the first half of 2024. Now we are launching our product broadly says Rickard Nikander, Senior Product Manager for High Temperature and Heat Exchanger Tube EMEA, at Alleima.

“Working with Alleima we were able to get the right material solutions for our project helping to have an efficient, profitable and sustainable process,” says Daniel Bergmann, Operations Manager at ISOMIL.

“Now we are delighted to introduce our special-grade metal Alleima product to the market. It is the perfect solution for industries where precision, reliability, and safety are paramount, including thermocouple sheathing, pyrometers, and heat tracing cables, where temperature control is important. Engineers need to have accurate readings to monitor core temperatures of a furnace, to avoid serious issues. Alleima had control over the entire production process, from research and development to bar production, extrusion, and cold pilgering, which ensures that the quality of “Alleima TD” meets the highest standards”, explains Rickard Nikander.

With over 900 advanced steels and alloys, Alleima helps reduce carbon footprint and energy consumption while increasing efficiency. The company’s production processes use 80% recycled steel and 96% fossil-free energy worldwide.

About Alleima

Alleima is a global manufacturer of high value-added products in advanced stainless steels and special alloys as well as solutions for industrial heating. Based on long-term customer partnerships and leading materials technology, they develop products for the most demanding applications and industries including products like seamless steel tubes for the energy, chemical and aerospace industries, precision strip steel for white goods compressors, air conditioners and knife applications, based on more than 900 active alloy recipes. It also includes ultra-fine wires for medical and micro-electronic devices, industrial electric heating technology and coated strip steel for fuel cell technology for cars, trucks, and hydrogen production.

Alleima, with headquarter in Sandviken, Sweden, had approximately 6,500 employees and revenues of about 21 billion SEK in about 80 countries in 2023.

Alleima AB

Tel.: +46 72 1452342