27/05/2021 – Teknor Apex receive “halogen-free” assessments from UL

Four new flame retardant wire and cable jacketing compounds

UL has recognized four new “Halguard” low-smoke, flame retardant jacketing compounds as “halogen-free”, as announced by Teknor Apex Company.

The compounds include new-generation EVA-based products with an enhanced balance of properties, and highly flexible TPE-based products that exhibit excellent oil and sunlight resistance. The assessment of halogen content was conducted in accordance with UL 2885 standard for the presence of fluorine (F), chlorine (Cl), bromine (Br) and iodine (I) at a maximum individual limit of 1,000 ppm. With the four new grades, there are now fifteen Halguard low-smoke, halogen-free flame retardant (LS-HFFR) compounds with UL AATJ2 component recognition as Halogen-free.

The new compounds, all with UL 94 flame ratings of V-0, are of two types:

1) EVA-based compounds for control, data, and transit cables. Halguard grades 58240 and 58242 provide high levels of flame retardance, resistance to heat shock and heat deformation, and ease of processing —the latter translating into increased throughput. The compounds enable cables to comply with UL 1685-FT4/IEEE 1202 standards for vertical tray cable and the UL 1666 standard for riser cable. Other applications include fiber optic data cables and cables used in transit infrastructure, as in the case of tunnels.

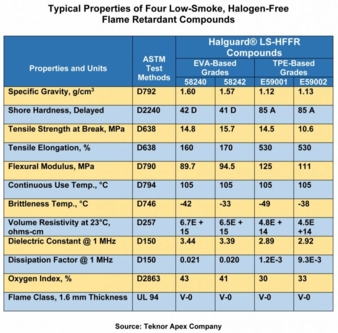

2) Highly flexible, oil- and sunlight-resistant TPE-based compounds. Incorporating elastomers, these two products comply with UL 62 and UL 758 standards for flexible cord and appliance wire, respectively. Halguard E 59001 exhibits 80% and 90% retention of tensile strength and elongation at break, respectively, upon immersion in IRM 902 oil for seven days at 60 °C. Halguard E 59002 retains 90% and 95% of tensile strength and elongation at break upon exposure for 720 hours in a weatherometer. Typical property data for these compounds appear in the accompanying table.

“The Halguard LS-HFFR product line provides properties to meet a wide range of applications, and the growing list of grades with ‘halogen-free’ assessments by UL further expands options for customers,” said David Braun, wire and cable industry manager for the Vinyl Division of Teknor Apex. “We will continue to develop Halguard compounds which can comply with this UL assessment in order to provide customers with readily available component recognition, which enables them to accelerate speed to market for their products.

Halguard LS-HFFR compounds are available worldwide.

Teknor Apex

Tel.: +1 401 725-8000

About Teknor Apex

Teknor Apex Company, a privately held firm founded in 1924, is one of the world’s leading custom compounders of plastics. Teknor Apex produces flexible and rigid vinyl, thermoplastic elastomers, nylons, color masterbatches, specialty chemicals, and hoses. The company is headquartered in Pawtucket, RI, U.S.A. and operates thirteen manufacturing facilities worldwide in the United States, Belgium, Germany, China, and Singapore. To learn more visit: www.teknorapex.com.

The Vinyl Division of Teknor Apex Company is a leading manufacturer of custom compounds, including “Apex” flexible and rigid vinyl, “Flexalloy” vinyl elastomers, “Fireguard” low-flame, low-smoke compounds, and “Halguard” low-smoke, halogen free, flame retardant compounds and elastomers. The Division is a global supplier to the appliance, automotive, construction, medical device, wire and cable, and other industries.