19/07/2022 – EMI shielding effectiveness on a wide range of frequencies

EMI shielding effectiveness on a wide range of frequencies

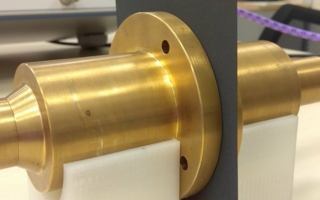

The ‘PDT’ is a disruptive technology in terms of innovation and environmental sustainability, unique in the sector. © Tenova

18/07/2022 – Standard for the product category “rules of metal finishing machines”

Standard for the product category “rules of metal finishing machines”

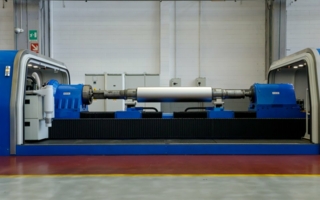

The “ZSK 70 Mc18” twin screw extruder that Coperion is presenting at “K 2022” has a 70mm screw diameter and is equipped with numerous features that improve handling and enable increased efficiency in compounding and recycling. © Coperion

15/07/2022 – Coperion and Coperion K-Tron at “K 2022”

Coperion and Coperion K-Tron at “K 2022”

The “Autac 300” is used for temperature measurement and control for applications with conductor preheaters or post annealing re-heat stages. © Zumbach

14/07/2022 – New in-line induction wire preheater family

New in-line induction wire preheater family

CRU is to hold its flagship CRU Wire+Cable Conference in the UK for the first time on 25-27 July 2022. © CRU

14/07/2022 – Conference will be held from 25-27 July 2022

Conference will be held from 25-27 July 2022

Models such as the “Combi-FSE” focus on heavier duty application for industry sectors such as steel or tubes and pipes. © Combilift

13/07/2022 – New electric sideloader from Combilift

New electric sideloader from Combilift

BP and Thyssen Krupp Steel form a strategic collaboration to support the decarbonisation of steel, including the supply of low carbon hydrogen and renewable power. © Thyssenkrupp Steel Europe