01/08/2022 – Carbon reduction and usage of renewable feedstock

Sustainability offering for the wire and cable industry

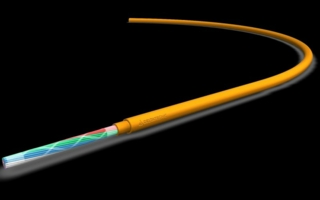

Latest Dow technologies are designed with safer materials and a strong commitment to carbon reduction and usage of renewable feedstock for high productivity, high-speed communications.

Dow returned to “wire” 2022 to showcase solutions with the ability to support customers on their sustainability journeys. These offerings are conceived to help cable manufacturers and utilities with the added value demanded by a high productivity and high-speed communication world.

Sustainability at the core

At “wire”, Dow introduced the theme “Infrastructure Net Zero”, highlighting its commitment to increasing sustainability outcomes for the industry through technologies that use safer materials, enable carbon footprint reduction in the manufacturing process, and use of renewable feedstocks.

“Dow solutions, when applied by our customers in the wire and cable industry, make up the infrastructure of our high-speed, connected world,” said Edit Berczi, Marketing Manager for wire and cables in Europe, Middle-East and Africa. “These solutions have been relied on for years by our customers for their durability and reliability. Now, our products go even further. By working with our value chain partners and investing in innovation, we are developing a new generation of solutions that can help enable the reduction of CO2 emissions and energy savings, hence decreasing the overall carbon footprint. We’re excited to return to Wire 2022 to connect with our customers and value chain partners to discuss how we can work together to reach our vision of Infrastructure Net Zero.”

Enabling global transformation

Dow introduced “HFDD 4201”, a new technology that is part of the “Endurance” family of “Next Gen XLPE” compounds for power transmission. “HFDD 4201” has the potential to transform the cable manufacturing process by cutting down long degassing periods by 80%. Cable manufacturers will benefit from: Shorter cycle times in the manufacturing process, lower inventory costs and reduced greenhouse gas emissions. The “HFDD 4201” is a response to the ever-increasing demand for power while reducing the potential impact on the environment and economic costs.

Dow Europe GmbH

Tel.: +41 78 7841724

www.dow.com