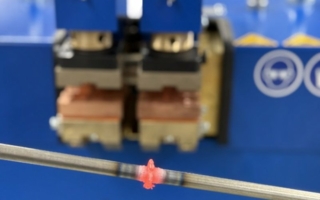

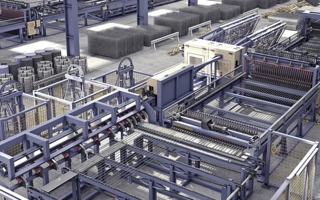

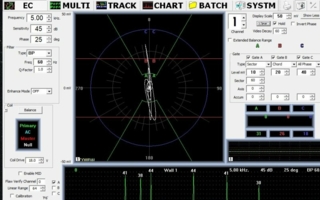

18.10.25 – The double pressure welding (DD) process for non-ferrous metals

The double pressure welding (DD) process for non-ferrous metals

In modern manufacturing technology, the joining of non-ferrous metals such as aluminum, copper, and other alloys is becoming increasingly important. Especially ...