08/04/2025 – Magnetic Analysis: reliable nondestructive testing

Detecting welds in the wire industry

Quality control is the backbone of the wire industry, where precision and reliability are non-negotiable. Defects like butt welds in insulated conductor cables can jeopardize the integrity of a product, leading to costly returns and damage to a manufacturer’s reputation.

Magnetic Analysis Corporation (“MAC”), a pioneer in nondestructive testing solutions, is helping wire mills tackle these challenges through its “Minimac” digital eddy current test equipment.

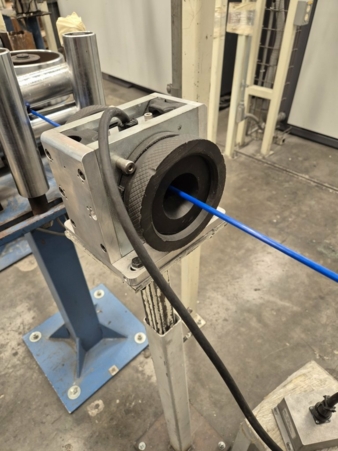

Butt welds, an unavoidable byproduct of high-speed wire production, can present a significant hurdle for wire manufacturers. These defects have been rejected outright by end-users, making it essential for manufacturers to detect and remove them during production. MAC’s “Minimac” digital eddy current test instrument has become an answer for wire manufacturers facing these quality rejects. The “Minimac”, designed for high performance and cost-effective detection of these butt welds, has recently helped a premier wire mill in Mexico. After a successful on-site demonstration, the company incorporated five “Minimac” systems into its production line. These systems now inspect insulated copper cables ranging from 2.5mm to 10mm in diameter, ensuring that defective sections are identified and removed before shipment. The “Minimac” features advanced encircling coil sensors and a “CP65NS” coil platform, allowing for accurate positioning and vibration control during high-speed testing (currently operating at 120m/min).

The results have been remarkable. Customer returns due to weld defects have been virtually eliminated, and the company is now exploring the possibility of expanding testing to multi-conductor cables at speeds of up to 200 meters per minute. This level of precision and efficiency has solidified their reputation for delivering reliable, high-quality products.

For nearly a century, MAC has been a trusted leader in nondestructive testing, providing tailored solutions for industries worldwide. With the “Minimac”, wire manufacturers can confidently meet the highest quality standards, ensuring their products exceed customer expectations and have a brand reputation that stands out in a competitive market.

For more information on how MAC can help your company maintain impeccable quality, visit https://www.mac-ndt.com/minimac

Magnetic Analysis Corporation

103 Fairview Park Drive, Suite 2

Elmsford, New York 10523-1544, USA

Tel.: +1 914 530-0015

info@mac-ndt.com

www.mac-ndt.com