04/12/2024 – “IM-ECO“ by EVG convinces at Tammet Oy in Finland

New welding system for the production of fence and industrial mesh

As a specialist for the production of welded grids, the Finnish company Tammet Oy has purchased the newly developed “IM-ECO” welding system from the Austrian machine and plant manufacturer EVG in the course of “wire 2022”. Two years later, both sides enjoy a production performance that has even exceeded the already high expectations.

The right investment decision in a challenging time

“On the one hand, the decision was easy for Tammet to make due to the extremely successful operation of several EVG machines,” says CTO Stefan Källberg. “In addition, we quickly realized during the project phase that EVG had met the current requirements of our customers exactly with this development and the focus on small production batches, high quality requirements, low manufacturing tolerances and very extensive product specifications. With the fully automatic ‘IM-Eco’ welding system, changeover times can be drastically reduced when changing products. This enables us to respond very efficiently to the increasingly rapidly changing requirements of the market and to optimize our entire production process in the production of small and medium-sized batches.”

EVG also presented the extraordinary flexibility of their new “IM-ECO” at this year's “wire” trade fair in Düsseldorf. Double wire mesh and high-security fence mesh of type 358 were produced every day and complete system changeovers were demonstrated within 90 min. to an impressed trade audience. As a rule, after the changeover, of course, production can be carried out in the usual quality without waste from the first mesh on.

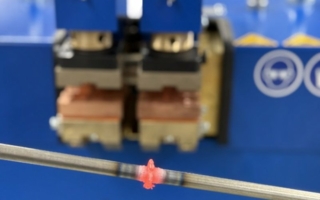

New patented technologies enable the production of mesh with minimal wire overhangs without trimming cut, i.e. without material loss or waste. EVG is addressing the ever-increasing importance of energy with the new medium-frequency direct current welding technology “Ecoweld”, which ensures uniform and standard-compliant welding node strength with minimal energy input.

The most important features of the IM-ECO

– Processing of pre-cut line and cross wires in the diameter range 2.5mm – 8.0mm, bright or galvanised

– Fully flexible wire spacings, starting at 25mm (line wires) and 12,25mm (cross wires)

– Feeding of the cross wires to the top or to the bottom of line wires, for the production of single and double-wire mesh

– Quick and easy changeover

– Zero waste production - no trimming, even for 358 security fence panels

– Modular design suitable for a very wide range of customer requirements

– DC welding technology “EVG-Ecoweld”

– Connection to “Wire Up” – the digital platform for EVG machines

Experience and quality awareness on both sides

“The decades-long cooperation with EVG is characterized by trust and continuity. We know that we can always rely on the excellent service and quality of the machines. This is very important to us,” emphasizes the management of Tammet.

Thomas Kügerl, Product Manager at EVG, adds: “Professional feedback from customers is just as important to us. This will ensure that the high requirements from the fence and industrial mesh industry will continue to be met in the best possible way in the future and that new trends will be taken into account in our developments.”

EVG Entwicklungs- und Verwertungs-Gesellschaft m.b.H.

Gustinus-Ambrosi-Strasse 1-3

8074 Raaba-Grambach, Austria

Tel.: +43 316 4005-0

sales@evg.com

www.evg.com

Tammet Oy

Metallikutomonkatu 1

10600 Tammisaari/Finland

Tel.: +358 201 450-201

info@tammet.fi

www.tammet.fi