02.06.22 – Testing solutions from Rohmann

Testing solutions from Rohmann

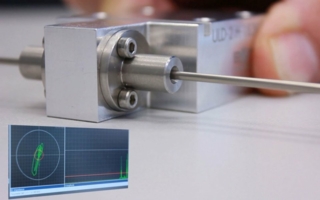

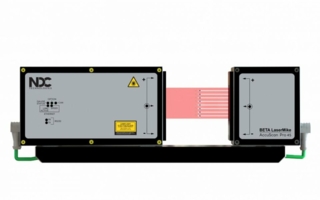

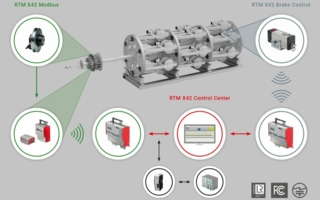

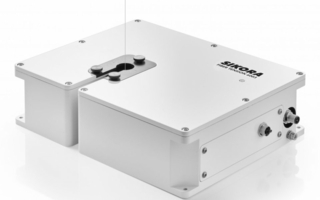

Rohmann GmbH is a company situated in Frankenthal in the Palatinate in southwestern Germany and has been developing and marketing eddy current testing ...