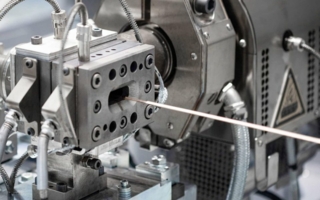

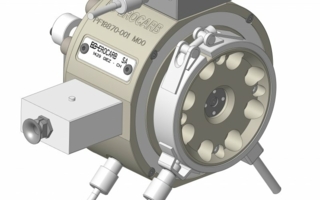

The new “E2HN30” head can manufacture single, double or triple-layer cable, depending on its configuration. © Erocarb

27.03.24 – Extrusion

Extrusion

Since its foundation over four decades ago, Erocarb SA has established itself as a leading manufacturer of custom extrusion heads. With a rich heritage ...