27/03/2024 – Extrusion

From extra small to very large

Since its foundation over four decades ago, Erocarb SA has established itself as a leading manufacturer of custom extrusion heads. With a rich heritage of over 45 years' experience, the company has evolved to meet the complex needs of the industry.

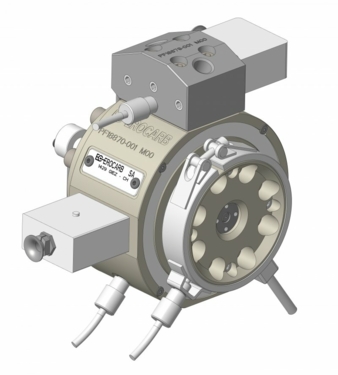

In its ongoing quest to satisfy the industry's specific requirements, Erocarb SA is pleased to present its latest addition to its product range - the “E2HN30” triple-layer extrusion head, especially designed for the manufacture of small cables.

Very small cables require very little plastic. Extrusion flow rates are therefore very low.

In fact, some polymers do not tolerate slow flow velocities or processing times. Some PVCs can start to degrade with heat and damage the extrusion head, XLPEs can start to cross-link if the reaction is chemical, and some engineering polymers can see their mechanical characteristics reduced.

To minimise residence time in the extrusion head and optimised flow speed, flow channels are kept to a minimum thanks to the very compact size of the parts.

Triple-layer for small cable

The new “E2HN30” head can manufacture single, double or triple-layer cable, depending on its configuration. Both solid multilayer or foamed, such as skin-foam-skin. It is suitable for conductor diameters from a few tenths of a millimeter up to 2mm, and can be optimized for a wide variety of different polymers. Its fine-tuning centering allows both fixed centering and slight adjustment. This new product will be displayed on their booth at “wire”.

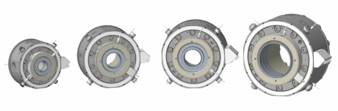

Extending their range of “compact” crossheads

Erocarb is delighted to announce a significant expansion of its range of "compact" extrusion heads, originally designed for small to medium-sized single-layer cables. This major evolution now makes it possible to cover cables up to more than 230mm. Thanks to its reduced dimensions, their extended range ensures complete coverage, meeting the varied needs of cable manufacturers with minimal footprint. This initiative demonstrates the commitment to innovation and positions Erocarb as a complete crosshead solutions provider, ready to meet industry challenges with quality, high-performance products.

Crosshead accessories

In addition of all crossheads, to simplify operations and improve production efficiency, various accessories are available. From 4mm heads to the largest extrusion heads, the “ETEL” telescopic system facilitates the removal and cleaning of distributors directly on the extrusion line. Moreover, manual, hydraulic or even pneumatic bypass modules save time and practicality during maintenance operations. As a further complement, a range of vacuum connections, carts and supports are also available. And last but not least, Erocarb's offering also includes all variations of wire guides and dies, covering all extrusion processes: compression, semi-compression, semi-tube, tube, etc.

wire 2024, hall 10 booth C 60

Erocarb SA

La Pomelaz 6, 1429 Giez/Switzerland

Contact person is Frédéric Vaucher

Tel.: +41 24 446 23 03

info@erocarb.ch

www.erocarb.ch