22/09/2023 – Wire processing / braiding

Automated production of wire based stent implants

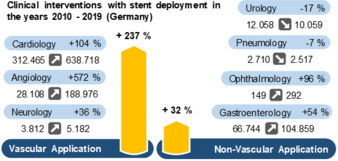

According to WHO, cardiovascular disease and cancer will be the leading causes of death. In 2016, cardiovascular diseases accounted for 17.9 million deaths, followed by cancer with 9 million. Growing population and longer life expectancy contribute to the rise in diseases. Stent implants are in high demand to address occlusion caused by atherosclerosis and tumors. In Germany stents are primarily used in coronary and peripheral vessels, as well as cerebral blood vessels. Stents are also used in non-vascular systems. Stent procedures are increasing globally across medical specialties [MGJ+22].

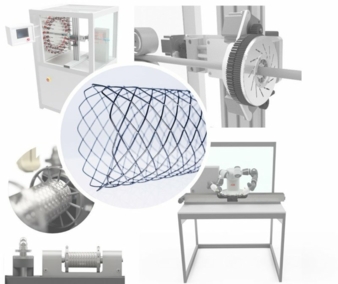

Design and manufacturing processes of stent implants vary based on their application. Laser cutting and wire-based braiding are popular methods. Cut stents are used in small-diameter vessels like coronary and cerebral vessels, while wire-based stents are preferred for larger vessels and non-vascular applications. Wire-based stent production relies heavily on manual steps, leading to high costs and complexities. Manual work contributes to 80% of manufacturing costs [MGJ+22]. Research at RWTH Aachen University focused on automated approaches for atraumatically braided stent production. Two processes were implemented: automated single-thread braiding (AEF) and atraumatic multi-thread braiding (AMF). The goals were to develop and implement automated manufacturing processes, validate mechanically compliant stent implants, and assess economic efficiency [Mer23].

The automated single-thread braiding process, automates the manual single-thread braiding using a core system, storage systems, and a positioning unit. A collaborative robot handles the braiding process, while other modules were developed within the project. Atraumatically ended stents were successfully produced and validated [Mer23].

The atraumatic multi-thread braiding process manipulates the wire deposit in s-curves during round braiding to create perforated braids and atraumatic structures. A 3-axis manipulator controls wire deposition, and the process has shown suitability for producing atraumatic multithread stents [Mer23].

Mechanical validation of both methods followed DIN EN ISO 25539-2. Comparing basic target values, the automated implants demonstrated mechanical properties comparable to manually braided benchmarks. Thermal treatment can further align mechanical properties. Evaluation of economic efficiency involved developing concepts for fully automated production lines and calculating process costs. The automated processes reduced manufacturing costs by 70% to 73% compared to manual procedures [Mer23].

The global demand for stent implants is rising, especially for wire-based implants due to their advantages in cost and flexibility. However, manual manufacturing processes lead to high costs and economic challenges. A research field at the Institut für Textiltechnik of RWTH Aachen University developed and validated automated processes for atraumatic stent production, showing cost-effectiveness. Automated single-thread braiding has high application potential. Automation enables cost-effective, customer-oriented production, which is crucial in a competitive and regulated market [Mer23].

Gratitude is expressed to all project partners for their collaboration.

This is an excerpt from the dissertation thesis "Evaluation of automated processes for the production of wire-based braided stent implants", published by Shaker Verlag (ISBN 978-3-8440-9007-9). A shortened digital version can be found in the corresponding white paper “Automated Production of Wire Based Stent Implants” published by Verlag Meisenbach. The full digital version is available for free on the library pages of RWTH Aachen University. For further inquiries, please contact the author.

Sources

[MGJ+22] Merkord, F.; Grimm, Y.; Jaworek, F.; Gries, T.; Overview on the Current Global Market of Stent Implants – Market Research 2020 – 21; Shaker Verlag, Düren; April 2022

[Mer23] Merkord, F.; Evaluierung automatisierter Verfahren zur Herstellung drahtbasiert geflochtener Stentimplantate, Shaker Verlag, Düren; März 2023

The author of the article is Felix Merkord.

ITA – Institut für Textiltechnik

RWTH Aachen University

Otto-Blumenthal-Strasse 1

52074 Aachen/Germany

Contact person is Felix Merkord

Tel.: +49 241 80-49158

felix.merkord@ita.rwth-aachen.de

www.ita.rwth-aachen.de