22.04.23 – Surface treatment

Surface treatment

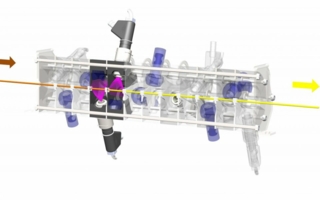

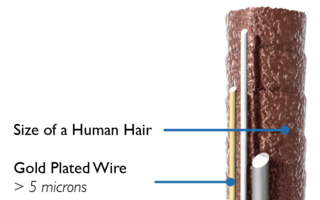

The German manufacturer of equipment for the wire industry, Kieselstein, has been successfully supplying the US market for many years. By focusing on the ...