18/04/2023 – Surface treatment / Blasting

Wet blasting system for wire and cable finishing

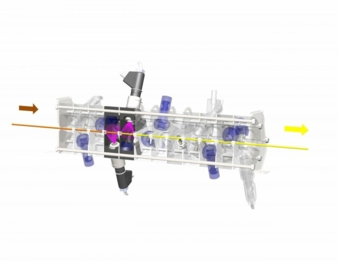

Designed specifically for the surface finishing of wire and cable, the automatic Vapormatt “Profelis” wet blasting system creates a highly clean reactive surface on wire, cable round bar and other strip products.

Wet blasting is a surface finishing process that uses a suitable abrasive media, water and pressurised air to clean a vast range of different metal and composite products, including wire and cable. The “Pofelis” is an in-line system that can be configured right to left or left to right to suit existing manufacturing setups.

Controlled via an intuitive colour HMI, it features 4 blast guns at 90° intervals as standard or 8 blast guns at 45° intervals for maximum 360° coverage. There’s also the option of dosing control for corrosion inhibitors and degreasing agents if required. Once the product is wet blasted, heated rinsing and drying completes the finishing process.

The new system has been built with ease of maintenance in mind with all components around the blast manifold easy to reach. There is also a rinse gun to help clean down the system after use, a pivot out pump and Vapormatt 4.0 for remote diagnostics and the timely supply of spare parts.

Based in the UK, Vapormatt supplies some of the largest manufacturers around the world. Ryan Ashworth, Head of Sales and Marketing, comments; “The previous model of our unique Profelis system was a huge success for us. This new model builds on that success with lots of useful new features like an automatic door, integrated heating and drying and Vapromatt 4.0 – our IIOT solution.”

Controllable variables ensure the perfect finish can be achieved on the surface of the wire or cable.

The company’s “Profelis” machine is purpose built for wire and cable and is very effective at finishing:

– Overhead power cable – thoroughly cleaned and given a non-specular finish for improved current carrying capacity.

– Aluminium and copper feeder wire – thoroughly cleaned, with imperfections and oxides completely removed prior to extrusion.

– Steel wire – thoroughly cleaned with graphite and heat scale completely removed in preparation for forming, machining and heat treatment.

– Carding wire – thoroughly cleaned with all heat scale, grease, discolouration, and burrs completely removed. Carding teeth are precisely honed for extra durability.

– Submarine communication wire – thoroughly cleaned and left with a reactive surface that is perfect for bonding with an outer sheath layer.

The “Profelis” has a blast gun manifold that ensures complete 360-degree finishing. It also features integrated rinsing and drying and sits in line with existing production to ensure throughput is as rapid as possible.

For wire products throughput can be significantly increased by Vapormatt’s patented micro gun technology. Multiple strands of wire can be finished at the same time using a common wet blast slurry feed that is not only more productive but uses much less compressed air too. To help with the wire extrusion process, the company also produces the “Cougar+” wet blasting machine that is highly configurable for extrusion die cleaning.

The first wet blasting machine was invented back in the 1940’s when Normal Ives Ashworth began looking at surface treatments with Frank Whittle during the development of the jet engine.

The Ashworth family still run Vapormatt to this day and have always ensured the company remains technical leaders in wet blasting technology thanks to continued investment in R+D.

Interwire 2023, booth 350

Vapormatt Ltd.

2 Robins Drive

Bridgwater, TA6 4DL Great Britain

Contact person is Miles Pluckwell

Tel.: +44 1823 257976

miles.pluckwell@vapormatt.com

www.vapormatt.com