12/05/2022 – Resilient laser cladding with high-power laser

Simultaneous processing of powder and wire

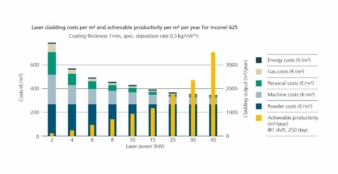

High-power diode lasers with outputs of ten or more kilowatts open new application scenarios for laser cladding. Particularly sustainable and resource-efficient coatings can be produced and applied, for example in automotive, machine construction and other industries. Together with industrial partners, the Fraunhofer Institute for Material and Beam Technology IWS has developed applications and specific processes for this laser class to industry readiness under the label “Hiclad”.

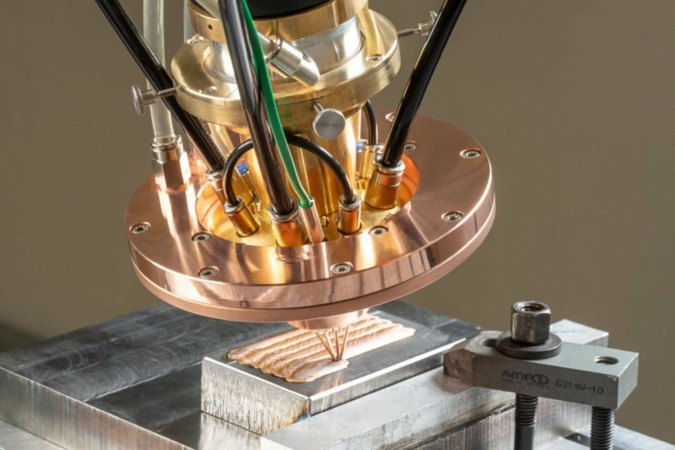

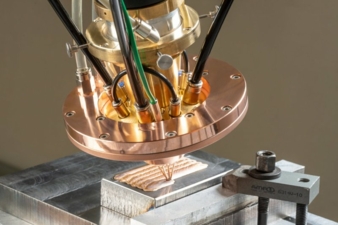

For the first time, simultaneous processing of powder and wire in various combinations becomes possible thanks to “Coax quattro”. © IWS

For the first time, simultaneous processing of powder and wire in various combinations becomes possible thanks to “Coax quattro”. © IWS

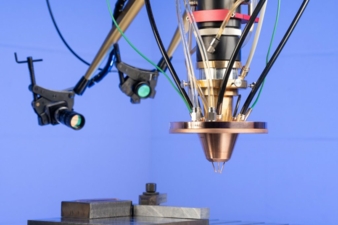

One core element of the “Hiclad” family is the innovative “Coax quattro” laser cladding head. A laser beam runs through the center of the nozzle, around which up to eight separately controllable channels feed wires and powders. © IWS

Measurement and control hardware developed at the Fraunhofer IWS serves as a key component to control the quality of the complex processes. © IWS