17/10/2025 – Researchers aim to automate air gap measurement

Quality assurance in the production of electric motors

Fully automating the production of electric motors and making an important contribution to quality assurance: these are the goals of the new “MotorInspector” research project.

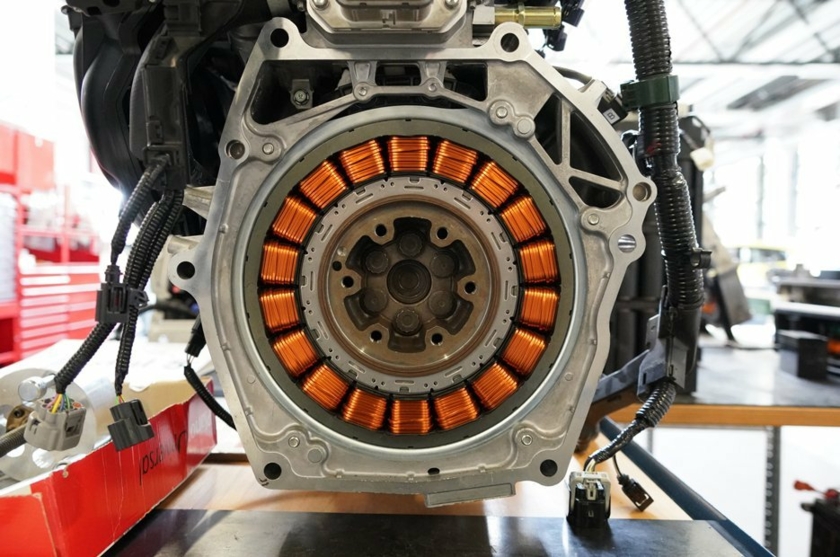

A look inside an electric motor: The narrow air gap between the rotor and stator has a significant impact on efficiency and service life. (Photo: jrgn_flow, https://stock.adobe.com/) © IPH Hannover/jrgn_flow (stock.adobe.com)

Electric motor production: The aim of the “MotorInspector” research project is to improve quality control. (Photo: industrieblick, https://stock.adobe.com/) © IPH Hannover

A look inside an electric motor: The narrow air gap between the rotor and stator has a significant impact on efficiency and service life. (Photo: jrgn_flow, https://stock.adobe.com/) © IPH Hannover/jrgn_flow (stock.adobe.com)

“MotorInspector” research project: In this project, IPH – Institut für Integrierte Produktion Hannover gGmbH and MFP Messtechnik & Fertigungstechnologie GmbH are working together on automated gap measurement for electric motors. (Logo: “MotorInspector” research project, https://motorinspector.iph-hannover.de/) © IPH Hannover