04/09/2024 – Auxiliary materials

Innovative lubricants revolutionize the cold forming of metals

Metals can be processed into wires by cold forming - an extremely complex process. However, the lubricants needed for this often do not meet the requirements of the end processors. As part of the KMU-innovativ project "Polyschmierung", five partners from industry and research have developed a new class of polymer lubricants.

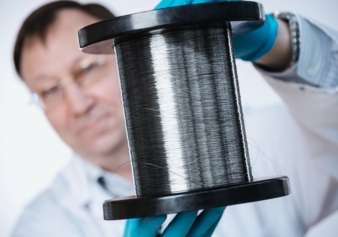

Lubricants based on polymers make the process of wire drawing significantly more environmentally friendly and economical. Kristin Stein © Fraunhofer IAP © Fraunhofer IAP