20/09/2021 – Fatigue strength diagrams

Development of fatigue strength diagrams for helical compression springs made of spring steel wire

At the end of 2020, the research project “IGF 19693 BR” at the TU Ilmenau in cooperation with the VDFI with the title “Renewal of the fatigue strength diagrams for cold-formed helical compression springs in DIN EN 13906-1 with a methodical and computational approach” was completed.

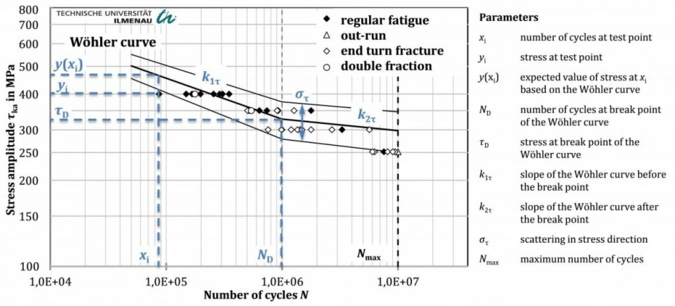

Fig. 2: Maximum likelihood evaluation of the results from the fatigue tests in the Wöhler diagram. © TU Ilmenau

Fig. 2: Maximum likelihood evaluation of the results from the fatigue tests in the Wöhler diagram. © TU Ilmenau

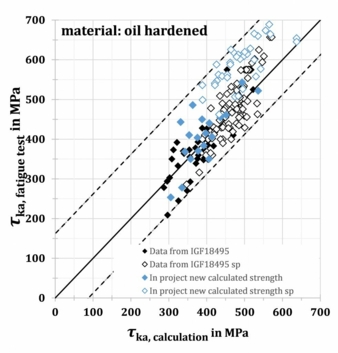

Fig. 3: Comparison of the calculated fatigue strengths with the experimentally determined fatigue strengths (sp - shot peened). © TU Ilmenau

Fig.4: Example of a new strength diagram (Diagram 8) with detailed information on the characteristic curves. In addition, correspondingly colored dashed lines are drawn as an indication of the static load. (The black dashed lines show the valid characteristics of the current standard for this spring variant). © TU Ilmenau