30/01/2020

Technology for copper wire production

SMS Group is going to present new plant concepts and innovations that meet the future demands of the tube and wire industry. Visitors to the SMS Group booth will also have plenty of opportunities to learn about the wide range of technologies and services.

As a systems supplier, SMS Group will present solutions for the full range of manufacturing materials for tube and wire products. For the copper industry, for example, SMS Group is going to show its “Compac Rod” technology for copper wire production. This technology package uniquely combines state-of-the-art technologies for gas-fired shaft furnaces, with a purpose-tailored casting system and a high-end rolling mill equipped with separately actuated individual drives. This modular plant concept is the perfect starting solution for producers wishing to take up the production of ETP- or FRHC-grade copper rod. The integrated production process, designed for a capacity of 5 to 7 tons per hour, is characterized by extremely low process costs.

For manufacturers of oil country tubular goods (OCTG), SMS Group has developed the “Thread View” measuring system. This gage checks in just a few steps whether the threads of pipes will be capable of withstanding the extreme stress acting on these pipes in the field. With Thread View, the measurements are much faster and more accurate than was achievable in the past with a completely manual inspection process, and it is even possible to inspect premium threads. An additional benefit is that the acquired measuring data can be used for the evaluation and detailed analyses of the production process, and for documentation purposes.

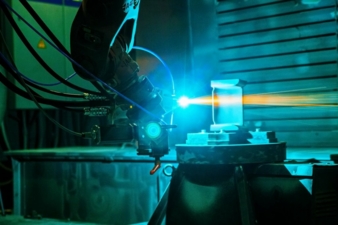

SMS Group’s “Perfect Spray” impressively shows how advanced surface coating can sustainably enhance the long-time performance of tubes. By combining kinetic electric arc spraying with the digital current-voltage source Perfect Spray , tube coatings become more resilient to wear and corrosion and thus longer lasting.

As the core element of an innovative automation concept for high-frequency tube welding plants, “X-Pact” Quicksetting assures that – after a dimensions change – the rolls are automatically adjusted to their new positions. Customers benefit from this data-based adjustment process in the form of extremely short change-over times.

SMS group will also present its new digitalization app “SMS-Metrics”, a tool that captures and stores machine and process data inline, i.e. during running production. The collected data can be called up in customized form via smart phone, tablet or PC. With SMS-Metrics, operators and managers can view the production data at any place in real time.

Also presented will be the prototype of the SMS Group “eShop”, which will allow customers to order spare parts or services conveniently via an online portal. eShop is another element of SMS Group’s digitalization strategy and an integrated part of the digital “Smart Maintenance Solutions” product family. SMS group invites trade fair visitors to learn about the wide range of functionalities provided by the new eShop and the various links and communication channels to other modules of the product family, such as Smart Alarm (central alarm management), Genius CM (Condition Monitoring), the electronic eDoc plant documentation system and IMMS, the integrated maintenance management system.

This year’s Tube & wire trade shows will also see the continuation of SMS group’s “Leading Partner Talks”. During the fair days, customers and partners from industry will talk about current projects and give their assessments of future trends and developments at the SMS Group booth. The program of the “Leading Partner Talks” will be available in March at www.sms-group.com/tw2020.

Visitors to the SMS Group booth will also have plenty of opportunities to learn about the wide range of technologies and services by means of which SMS group optimizes its customers’ plants – during their complete life cycle – in terms of sustainability, efficiency, reliability and safety.

wire/Tube 2020, hall 7a booth B 03/04

SMS Group GmbH

Eduard-Schloemann-Strasse 4

40237 Dusseldorf/Germany

Contact person is Thilo Sagermann

Tel.: +49 211 881-4449