10/04/2023 – Automatic straightening machines

Straightening with multiple working rotors

Eurobend offers a full range of high-performance automatic straightening machines for different wire qualities covering the diameter range from Ø2mm up to Ø12mm. The “MELC Polyline” series are multi-line wire straightening machines with simultaneously operating straightening rotors.

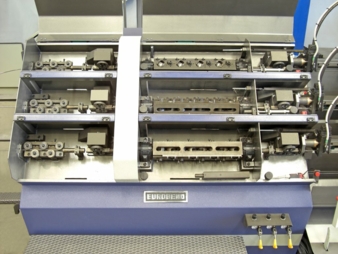

Photo 3: Three-line machine, model “MELC x3 MS” with mechanical stop length precision measuring system.

Photo 1: Three-line machine, model “MELC 2-10x3” with mechanical stop length precision measuring system. © Eurobend

Photo 3: Three-line machine, model “MELC x3 MS” with mechanical stop length precision measuring system.

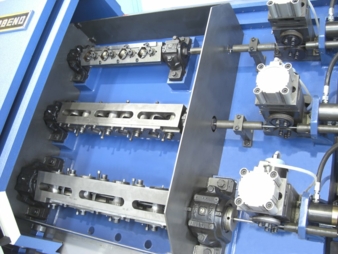

Photo 4: Two-line machine, model “MELC x2 MS” with mechanical stop length precision measuring system.

Photo 6: Three-line machine, model “MELC 2-10x3 MS”. Special version with sound isolation. © Eurobend