01/04/2024 – Transworld Engineering is ready to show its spring machines

Springing into innovation

Transworld Engineering Ltd, supplier of spring machinery, based in the UK, is set to exhibit at the prestigious “wire”, where they will proudly showcase and demonstrate a selection of their innovative range of products.

Their exhibition participation underscores the commitment to showcasing the latest innovations in spring machinery, positioning Transworld as a central hub for European spring and wire processing companies. They provide comprehensive manufacturing solutions, including high-quality machinery sales, and ensure unparalleled engineering support throughout the product lifespan, empowering spring manufacturers for efficient in-house part production.

Founded in 2009 by Philip Barrett, Transworld Engineering Ltd traces its roots to Barrett's research in China, specifically in Dongguan. During this time, he established valuable connections, fostering enduring friendships and strong partnerships with top manufacturers. Collaborating with Stuart Pilley, the company flourished, expanding its market internationally. Pilley's skills and ambition played a crucial role. In 2023, driven by his love for the industry, Pilley acquired the company, relocating the headquarters to Cradley Heath, marking a new chapter in Transworld Engineering Ltd.’s journey.

The company embodies a fusion of traditional customer care values with the contemporary aspects of technological advancement in its machines. At present, Transworld boasts a dynamic and continually growing team of young, highly skilled professionals dedicated to ensuring that the machines and after-sales services offered consistently meet or exceed expectations.

Engaged in ongoing research to provide optimal solutions to its customers, the company forged a partnership with Unison Ltd, a prominent player in tube bending machinery. This collaborative effort culminated in the joint acquisition of Pneuform, marking a significant development in their collective pursuit of excellence.

Pneuform wire bending machines

Pneuform emerged as an early innovator in the realm of CNC 3D wire bending. Presently, its machines for bending wire and small diameter tubes have become the benchmark within the industry, adopted by numerous manufacturers of beer coolers, drink dispensers, HVAC equipment, and small diameter automotive parts. Pneuform's range of wire bending machines encompasses rotary head models, flat rotary line bending machines, and enamelled wire bending machines. Offered in both 2-axis and 3-axis versions, Pneuform's machinery accommodates outside tube diameters ranging from 3mm to 11mm in stainless steel and 3mm to 15mm in copper.

Transworld's machines at “wire”

Visitors will be able to discover the tube and wire bending technologies offered across the Transworld and Pneuform machine tool ranges. Between their machines, they chose to put on display three: “TWE-830”, “TWE-NM1220X“ and “TWE-1245”.

“TWE-830”: 8-axis high-speed CNC coiler machine stands out as one of their best-selling products in Europe, primarily due to its capacity to efficiently handle a widely used range of wires (Ø1mm-3mm). Noteworthy features include the machine's speedy setups, facilitated by its versatility, and the rapid transition between different jobs and right and left-handed springs.

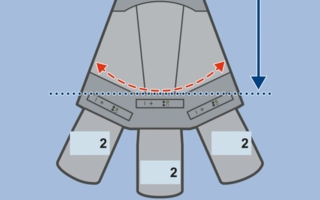

“TWE-NM1220X”: They are set to reveal their flagship CNC wire former, featuring 12 axes and an integrated picking robot to showcase the remarkable capabilities of the unique X-shaped machine. Its 4 slides are equipped with vertically and lateral movement and multi-tooling holders, facilitating the setting up of the machine.

“TWE-1245”: An efficient larger and powerful wire former that can craft round and flat wire shapes (Ø 1.2mm-4.5mm), including clock springs. Optional add-ons include a bending station, ideal for larger legs, and a servo cutter for a smooth, burr-free finish.

wire 2024 , hall 16 booth G 17

Transworld Engineering Ltd

Waterfall Lane Trading Estate

Unit 7D, Waterfall Lane,

Cradley Heath,West Midlands B64 6PU/U.K.

Contact person is Benedetta Migliorini

Tel.: +44 121 7400189

bm@transworldengineering.co.uk

www.transworldengineering.co.uk