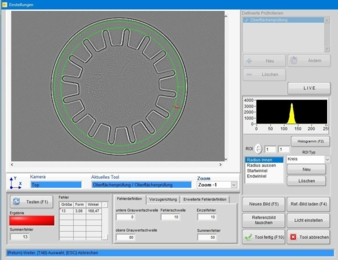

28/06/2022 – “Opti Sort” with next generation “SFS” Technology

Sorting and inspecting machines

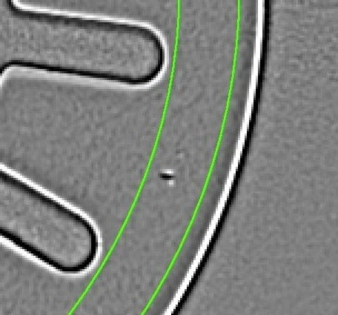

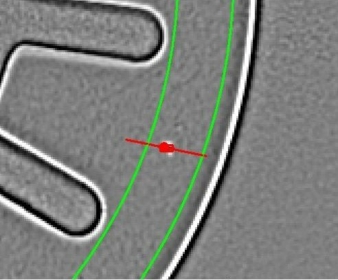

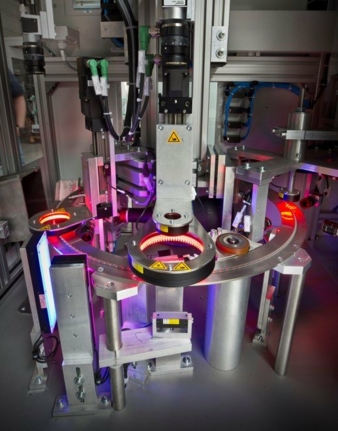

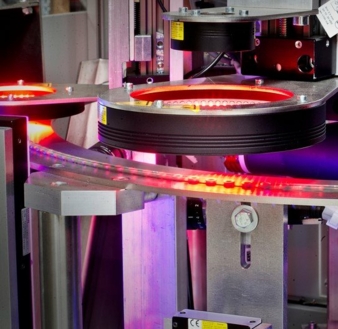

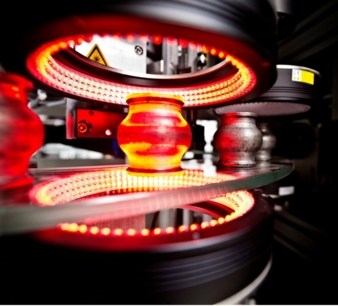

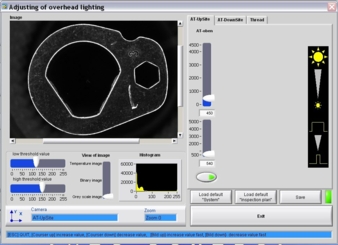

Gefra GmbH continuously improve their systems for the benefits of their customers, therefore they have advanced their “SFS” System (SFS = shape from shading) and are able to include all necessary components into a smaller camera system including the extensive lighting.