24/02/2023 – Wire drawing / Preparation

Savings thanks to internal wastewater treatment

High waste management costs for the disposal of industrial wastewater prompted Anka-Draht to think about ways to save money and to procure a wastewater treatment plant. The purification of the electroplating wastewater and the used wire drawing emulsion is now carried out by two “Vacudest” evaporators.

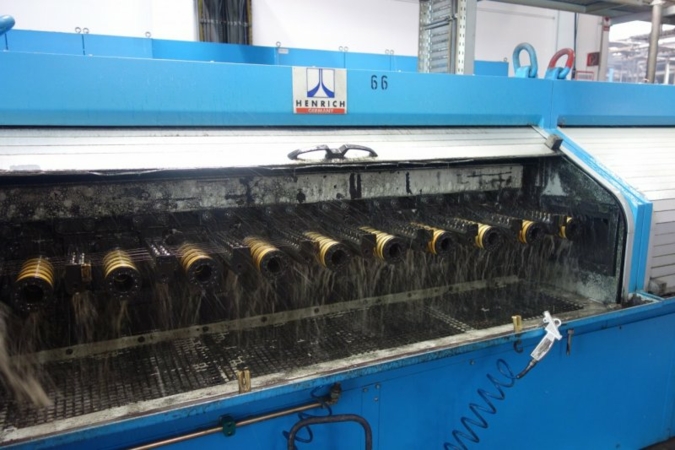

The “Vacudest M” treats the used emulsion from the drawing process so efficiently that the treated water is suitable as the basis for the new wire drawing emulsion. © Anka-Draht

The “Vacudest M” treats the used emulsion from the drawing process so efficiently that the treated water is suitable as the basis for the new wire drawing emulsion. © Anka-Draht

The “Vacudest S” reliably separates heavy metals and complexing agents from the electroplating rinse water used by Anka. © H2O