16/11/2020 – Wire processing / Rolling

Rolling of variable-diameter wire rod

The booming electric bike market requires new manufacturing processes for bicycle spokes. Aachener Maschinenbau GmbH (AMBA) developed the new spoke-blank reducing machine “DD-350”. Rolling provides high degree of flexibility in the manufacture of spoke blanks.

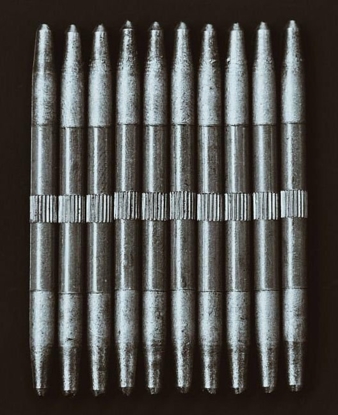

The new machine produces double thick end spokes with a diameter of only about 1.5mm in the middle. © Aachener Maschinenbau

The new machine produces double thick end spokes with a diameter of only about 1.5mm in the middle. © Aachener Maschinenbau

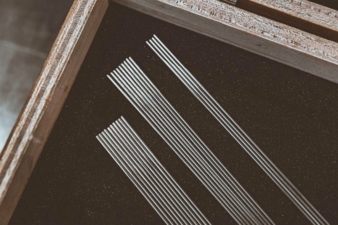

Double thick end spokes, which are thinner in the middle than at the ends, are mainly used for high-end bikes. © Aachener Maschinenbau

Double thick end spokes, which are thinner in the middle than at the ends, are mainly used for high-end bikes. © Aachener Maschinenbau