22/05/2025 – Niehoff technology: Flat wire drawing and annealing

Producing flat copper wire for cable shieldings

The copper shielding around the insulation layer is an important component of HV and EHV cables. It acts as a protection shield against electromagnetic radiation and is usually made of round wires. Flat wires, however, would be much more advantageous for several reasons.

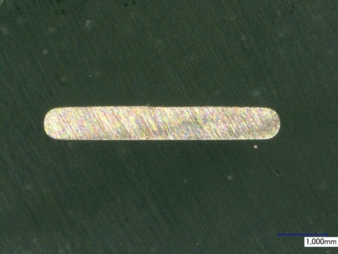

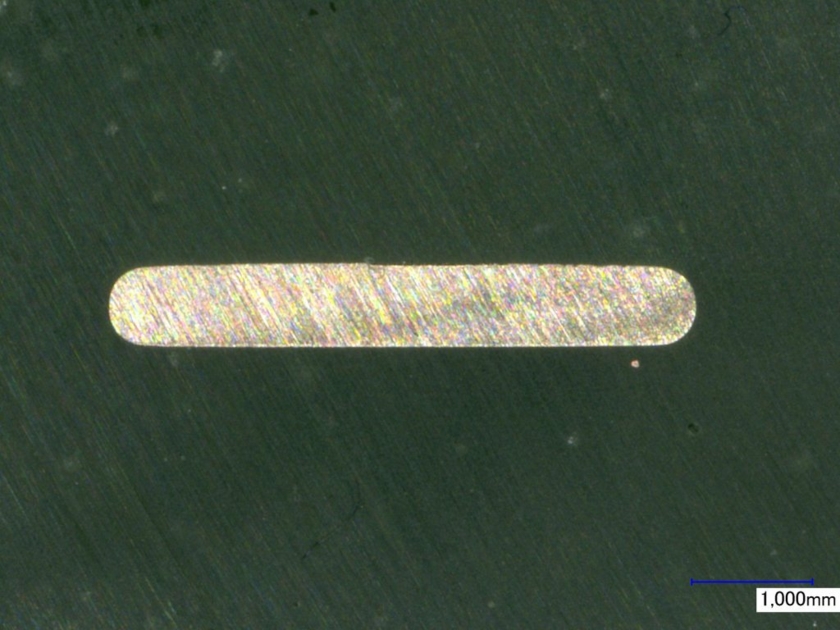

Fig. 4. Drawn flat copper wire, micrograph, after the ninth shaped die (finished die) (magnification = 50:1). Cross section: 3.192mm², width: 4.852mm, height: 0.677mm. © Niehoff

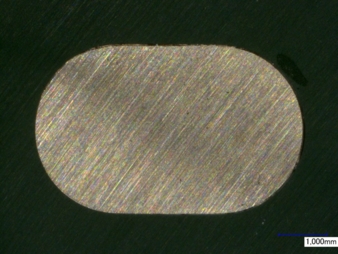

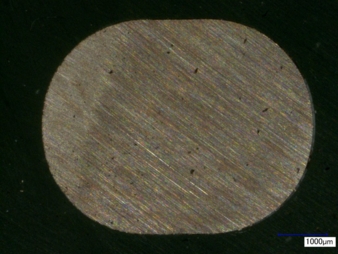

Fig. 2. Drawn flat copper wire, micrograph, after the first shaped die (magnification = 50:1). Cross section: 20.523mm², width: 5.560mm, height: 4.386mm. © Niehoff