30/08/2022 – The “4in1 electric axle” from Schaeffler

New drive for electric mobility

Schaeffler is focusing on electric mobility. The company is demonstrating this by simultaneously launching several new electric axle drives (electric axles).

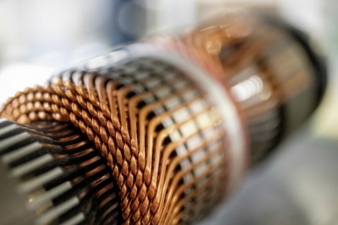

The highly integrated and compact housing of the 4in1 electric axle needs significantly less space than non-integrated systems. © Schaeffler

Matthias Zink, CEO Automotive Technologies: “Electric axles are a key element of Schaeffler’s electric mobility strategy.” © Schaeffler