30/08/2022 – The “4in1 electric axle” from Schaeffler

New drive for electric mobility

Schaeffler is focusing on electric mobility. The company is demonstrating this by simultaneously launching several new electric axle drives (electric axles).

“Electric axles are a key element of our electric mobility strategy,” says Matthias Zink, CEO Automotive Technologies at Schaeffler AG. Until now, up to three drive components were assembled in one compact unit. With the so-called 4in1 electric axle, Schaeffler is now going one step further by integrating the thermal management system as well as the electric motor, power electronics, and transmission into the axle drive. This makes the axle drive more compact and lighter and ensures greater comfort. A particularly efficient thermal management system also ensures that a car travels further on one battery charge and charges faster. Another new development are electric beam axles for pick-up trucks. In the future, Schaeffler will supply beam axles to automobile manufacturers, particularly in North America.

Efficiency factor thermal management

Heat is a scarce and valuable resource in electric cars. They do not have the waste heat from internal combustion engines for heating the interior, for example. Furthermore, particularly at high and low outside temperatures, the range and rapid charging capability essentially depend on whether, for example, the battery can be held in a suitable temperature window. “The thermal management system has a significant influence on the efficiency and comfort of the vehicle,” says Dr. Jochen Schröder, head of the E-Mobility business division at Schaeffler. The company therefore already offers thermal management systems for all types of vehicle powertrains and is continuing to develop them. A new approach is the combination of the drive components of a conventional electric axle with the thermal management system, which was an independent module in most cases until now. “This creates a highly integrated and compact complete system, which requires significantly less space than non-integrated solutions,” says Schröder. Furthermore, less energy is lost in the form of heat because unnecessary hoses and cables can be dispensed with. “In addition to the compact design, the greatest advantage of the 4in1 system is the optimized interaction of the individual subsystems,” says Schröder. This is because Schaeffler’s experts always consider the thermal behavior of individual drive components such as the electric motor or the power electronics as well as the most efficient and comprehensive thermal management of the entire vehicle. For example, an intelligent control system ensures that excess heat is efficiently dissipated from the power electronics and electric motor and that it is used in the interior of the vehicle. The temperature of the battery is also regulated in such a way that the car can travel further on one battery charge and that it charges faster.

The supplier realizes further efficiency benefits by bringing in a new heat pump, which is operated with the natural refrigerant, carbon dioxide. Not only does carbon dioxide have less impact on the environment than conventional refrigerant, it also has physical characteristics, which allow more efficient heating and cooling of vehicles. “By means of our 4in1 electric axle with an integrated thermal management system, we can achieve an even higher efficiency level of the complete system,” says Schröder. An efficiency level of up to 96 % is possible in an optimally designed system. Each additional percentage point translates into an increased range.

From individual component to complete system

With its 4in1 electric axle, Schaeffler is developing its most comprehensive drive system for electric cars so far. “Such highly integrated complete systems are attractive for both established automobile manufacturers and new players,” says Schröder. This allows a reduction in the development time and the costs for the complex new development of the entire drive. Nevertheless, the company will continue to offer to its customers individual components and subsystems for electric and hybrid drives such as electric motors, transmissions, bearings, and the thermal management system. The range also includes the combination of two or three drive components. Schaeffler is therefore opening up a particularly large market, especially since in the future electric axles will be used in vehicles ranging from passenger cars through to light commercial vehicles – with purely electric drives and drives based on fuel cells. This would extend also to tailored electric axles and components for the electrification of commercial vehicles and heavy-duty applications.

For the electrification of medium-duty pick-up trucks, particularly for the North American market, Schaeffler is developing and will manufacture an electric beam axle. In the electric beam axle, the electric motor, transmission, power electronics, and the entire rear axle are connected to each other and supplied to the customer as a ready-to-fit unit. Axles like these are more than two meters wide. Schaeffler has already secured its first orders for electric beam axles from automobile manufacturers. The company is therefore entering a new market segment for electric axle drives.

Global production network

Schaeffler manufactures components for electric axles at several locations worldwide. In September 2021, production started at its plant in Szombathely, Hungary. This production location is the Schaeffler Group’s first pure e-mobility plant and its new competence center for the manufacture of components and systems for electrified powertrains. In addition, components for e-mobility and integrated electric axle drives are manufactured in Taicang, China. A further production facility is being set up in Wooster, US, where hybrid modules are already being manufactured. And the new global lead plant for electric motors is now being built in Bühl, headquarters of Schaeffler’s Automotive Technologies division.

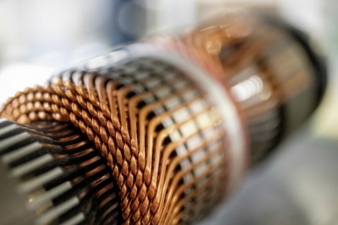

The company plays to its special strengths in the production of electric axles: Schaeffler is well versed in the production of individual components through to high-precision manufacturing methods such as stamping individual stator laminations for electric motors and the winding of rotors using innovative wave winding, for example. By using them, improvements can be achieved at the level of individual components, which together result in a more efficient complete system. In addition, the company is using its high level of production excellence to bring electric drives on to the market quickly in high volumes.

Schaeffler Automotive Bühl GmbH+Co. KG

Industriestrasse 3, 77815 Bühl, Germany

Contact person is Annett Fischer

Tel.: +49 7223 941 36 36

annett.fischer@schaeffler.com

www.schaeffler.com

Schaeffler Group – We pioneer motion

As a leading global supplier to the automotive and industrial sectors, the Schaeffler Group has been driving forward groundbreaking inventions and developments in the fields of motion and mobility for over 75 years. With innovative technologies, products, and services in the fields of CO?-efficient drives, electric mobility, Industry 4.0, digitalization, and renewable energies, the company is a reliability partner for making motion and mobility more efficient, intelligent, and sustainable. The technology company produces precision components and systems for drive train and chassis applications as well as rolling and plain bearing solutions for a multitude of industrial applications. The Schaeffler Group generated sales of approximately EUR 13.9 billion in 2021. With around 83,000 employees, the Schaeffler Group is one of the world's largest family companies. With more than 1,800 patent applications in 2021, Schaeffler is Germany’s second most innovative company according to the DPMA (German Patent and Trademark Office).