16/12/2022 – Specially developed for colouring PVC and the improvement of the final finish

Latest developments in masterbatch

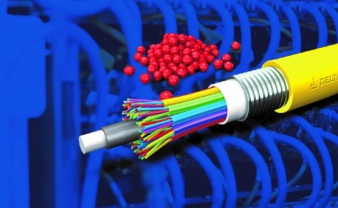

Delta Tecnic, a benchmark company in the production of masterbatch for colouring cables and PVC, showcased its latest product innovations at the „K 2022“ fair.

Delta Tecnic develops colour concentrate solutions that improve results and colour processing within the plastic transformation industries in all its applications, such as rigid and flexible profiles, calenders, pipes and cables. The masterbatches are specially produced for the colouring of rigid and flexible PVC, where very rapid dilution, colour homogeneity and a clean solution are required.

Colour concentrates for recycled PVC

In regards to the recyclability of PVC, it is crucial to recycle and reuse the plastic under the best conditions possible in order to avoid harmful environmental impacts. PVC can be recycled up to eight times depending on the application.

When a material is recycled with the intention to be reused for another purpose, it is common to end up with waste products of different colours. In these cases, it is advisable to apply an intense black colour concentrate so that the materials can achieve homogeneity as a whole in their recycling and thus return to the market with a renewed value. This is one possibility, although there are others as well.

For example, it is common for a company to want to recycle white materials, but here, a problem arises. When the PVC is reused, the initial colour is lost due to degradation, and the white materials tend to yellow. It is therefore important to use white masterbatches to create a more intense white. Thus, Delta Tecnic helps to renew the value of PVC waste through colouring in the recycling process.

Conductive PVC compounds and EMI shielding

Throughout its history, Delta Tecnic has manufactured conductive PVC compounds based on conductive carbon black technology. In the last decade, the company has introduced new raw materials such as Carbon Nanotubes, a new family of superconducting carbon blacks, as well as high-conductivity graphenes.

Likewise, there is an increasing demand in the cable sector for EMI shielding behaviours. This is shielding that prevents the penetration of high-frequency radiation, significant for the aviation and automotive industries. This type of compound reaches high DB insulation values and meets the demands of manufacturers of this type of cable.

Colour masterbatch for calendering

Obtaining a homogeneous colour in the final product of the calendering industry is a priority. Thanks to Delta Tecnic's range of products, calendering companies can produce PVC film more efficiently and cleanly, through simplified and reliable colour development.

In the current market there are companies that need hundreds of different colours for a series of short production runs. For example, if a company requires the formulation of 800 colours per year, it clearly does not make sense to demand such a large number of masterbatch references. In this case, single pigment masterbatches result in raw materials with excellent behaviour during dilution and dispersion to obtain the desired colour.

If only a few colours are required, Delta Tecnic offers the possibility of formulating custom colours according to the customer's requirements.

Colour masterbatch for profiles

Organizations have specific sets of needs to which Delta Tecnic offers reliable solutions. For example, the use of modern technology alongside older machinery leads to different requirements for the individual plants. In this context, Delta Tecnic offers masterbatch formulations that can be adapted to the processing of various extruders, helping to mitigate technological differences.

Delta Tecnic's products have been specially developed to obtain rapid dilution, colour homogeneity and a completely clean result. One of the most important factors in the window profiles industry is the colouring result. Optimizing the formula and making use of reduced-size pellets is a big step towards offering perfect colour homogenization. To this end, the company provides solutions for standard pellets, micropellets and small micropellets, among others.

Delta Tecnic

Pol. Ind. Molí de les Planes

Carrer Rec Molí de les Planes, s/n

08470 Sant Celoni, Barcelona, Sain

Tel.: +34 938 674 284

deltatec@deltatecnic.com

www.deltatecnic.com