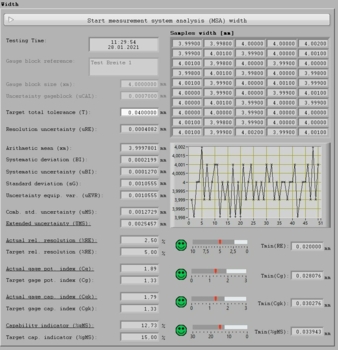

22/03/2021 – With integrated measurement system analysis (MSA)

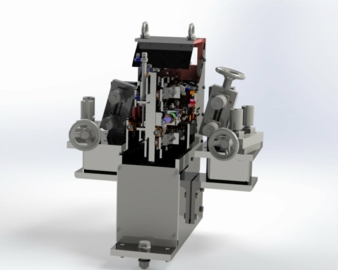

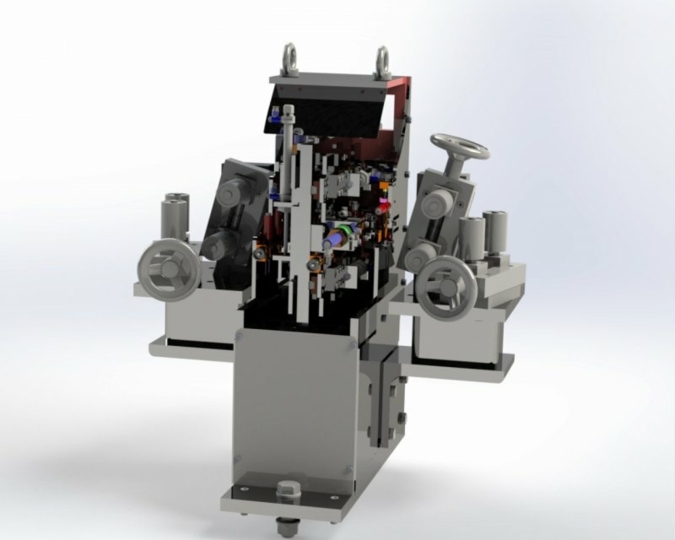

Inline measurement system “F-MAS 5.0”

As a manufacturer of rolling mills, Fuhr is constantly being challenged by increasing demands on the finished wire’s geometric precision. Accuracies of class 6 according to ISO 386 are almost standard. This implies a permissible deviation of ±0.0030mm for small profile wires with a nominal diameter of up to 3mm. If a process capability (Cp or Cpk) is also required, a spread of only ±0.0015mm remains in production.

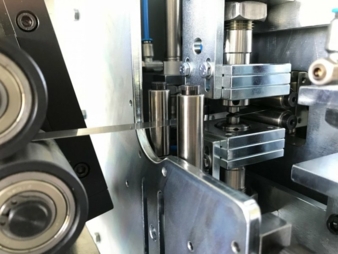

Fuhr relies on tactile measuring systems, in which the wire is scanned with diamond-studded, high-resolution displacement measuring systems. © Fuhr