05/09/2025 – wire Southeast Asia 2025, booth H 08

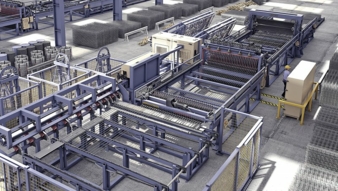

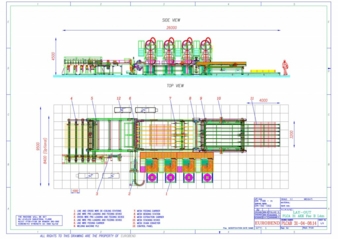

Fence panel production

For the 2D/3D fence panel production, Eurobend offers machines covering all productivity and automation demands: low and middle volume production of 2D/3D panels from pre-cut bars.