05/09/2025 – wire Southeast Asia 2025, booth H 08

Fence panel production

For the 2D/3D fence panel production, Eurobend offers machines covering all productivity and automation demands: low and middle volume production of 2D/3D panels from pre-cut bars.

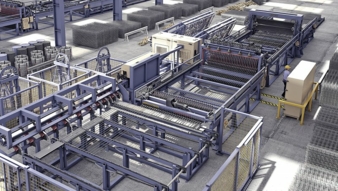

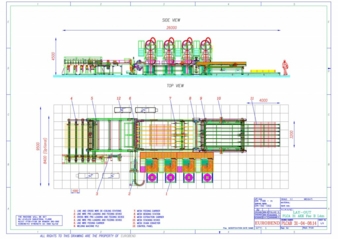

Produced by a “Multiline” Rotor-straightening machine of the “MELC Polyline” series with a mesh welding line of the “PLC ET” series with either stand-alone or an integrated bending unit for forming the 3D panels.

Fully automatic high volume non-stop production of 2D/3D and double bar fence panels from coils with one machine of the “AKK F” series. The high flexibility of the “AKK B” machines allow not only the production of large batches but also JIT production of smaller orders.

This new, innovative concept of the AKK eliminates all idle times and increases significantly the productivity in comparison to conventional welding lines. All advantages from off-coil and pre-cut welding machines and more, are combined in one machine. The mesh welding lines of the “AKK” series are capable of producing large and small batches-orders consecutively without any downtime. The concept behind the “AKK” series allows automatic mesh spacing and dimensions changes, making it the only flexible high production coil-fed mesh welding line, as it can produce all fence panel types instantly without any adjustments. The double line and cross wire de-coiling station replaces the non flexible arrays of coils of the conventional mesh welding machines. It offers a compact system layout requiring minimum floor space requirements.

No downtime when changing:

– wire coils

– line and cross wire spacing

– mesh dimensions

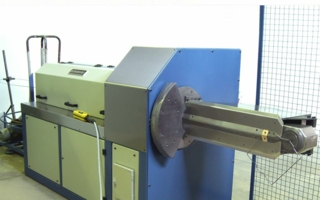

Equipped with the patented “Automatic Wire Orientation System”, which allows the use of a high speed roller straightening module for line wire feeding. The “AWOS” absorbs all wire straightening imperfections from the roller straightener. This unique Automatic Wire Orientation System ensures perfectly flat mesh panels regardless of wire and straightening quality. The cross wires can be welded above and below the line wires for compact stacking and the production of double wire panels.

The “AKK F” models with mesh advancing through a servo-driven carrier offer exceptional accuracy for production of precision industrial mesh, gabions and fence panels without overhangs, eliminating the need of trimming. An integrated mesh bending unit allows the in-line production of the 3D panels. Automated labeling systems are available.

wire Southeast Asia 2025, booth H 08

Eurobend GmbH

Alexanderstrasse 1

90547 Stein, Nuremberg/Germany

Tel.: +49 911 9498980

info@eurobend.com

www.eurobend.com