21/05/2022 – Automation: Uhing Motion Rolling Ring Drive

Faster processes, high precision

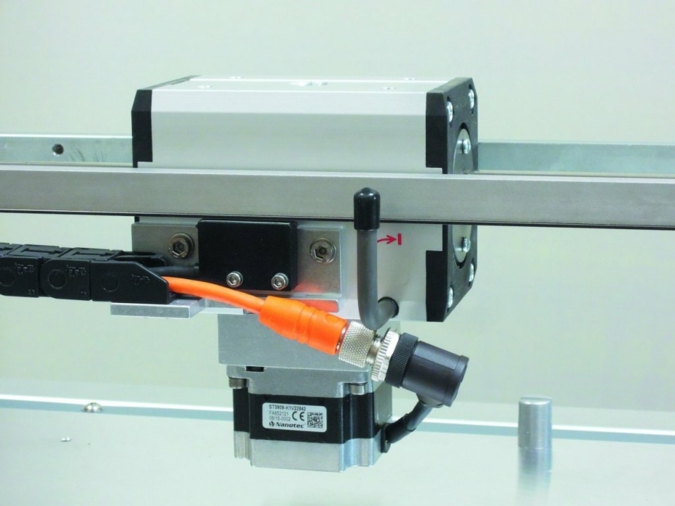

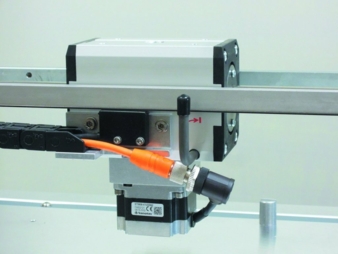

Uhing combines the robust and reliable rolling ring drive technology with a stepping motor connected to a Siemens “S7 PLC” controlling the pitch setting and the reversal. The degree of automation can be increased by implementing displacement transducers and sensors to meet individual requirements.