27/04/2025 – No tools, no hassle – just performance

Efficiency meets simplicity

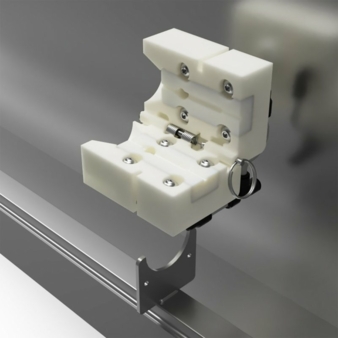

Keir Manufacturing has introduced its new “drop-in air wipes” for the 250 Series. The “250-KSPH” series will revolutionize the way their air wipes can be installed into existing mounts.

Keir’s “KSPH drop-in air wipes” offer a seamless, tool-free installation – simply slide them into existing mounts.

No tools, no hassle

This design ensures a secure fit while enabling Keir’s high-performance air wipe technology, utilizing our standard fully lined ceramic inserts sized specifically for your product diameters. It is the perfect choice for industries that prioritize efficiency and ease of operation.

Minimal maintenance, maximum productivity

Air wipes are a critical solution for drying, cleaning, and cooling extruded materials, and Keir’s air wipes require little or no maintenance, reducing downtime and increasing productivity. Whether used in tubing manufacturing, extrusion, or other wire processing, their user-friendly design streamlines operations, improving efficiency and consistency.

At the core of Keir’s air wipe technology is a precision-engineered chamber that controls the use of compressed air. As air decompresses to atmospheric pressure within this chamber, it accelerates to nearly the speed of sound in a thin layer surrounding the wire. This release of kinetic energy – stored when the air is compressed – enables superior performance with lower air consumption compared to traditional systems.

Key features and benefits

Custom sizing: Each insert is sized for a specific product OD for optimal performance, yet can accommodate a range, when desired.

Enhanced durability: Wear-resistant Alumina ceramic inserts help center the wire, preventing product damage.

Operator-friendly: Clamshell design with easy-to-replace inserts for hassle-free maintenance.

Corrosion resistance: Built with stainless steel hardware, including screws, springs, and pins.

Optimized air pressure: Designed to operate at 60 psi (4.14 bars) for the designated wire.

Customization options: Available in oval, rectangular, and acid-resistant variants.

Sure shot air wipe

The “Sure shot air wipe is a compact and versatile solution for wet wire applications, accommodating wire sizes up to 0.400" O.D.. Typically mounted with a 2” x 2” x 1.5” block, it can also be customized with multi-wire or multi-head manifolds with centers as close as 1 inch (25mm) – ideal for tight spaces.

Split shot air wipe

Keir’s clamshell style air wipe is a highly effective and convenient solution for your drying applications. This hinged design provides ease of use, opening to allow welds or extrusion bulges to pass through resulting in faster set-ups and less line breaks. Flexability of inserts swaps in minutes. Available in 250, 350, 450, 500 and 550 series.

Interwire 2025, booth 1900

Keir Manufacturing

133 McClean Road

28712 Brevard, NC/USA

Contact person is Kenny Greene

Tel.: +1 828 884-84444

greene@keirmfg.com

https://keirmfg.com