28/03/2025 – HMI for safe machine operation in the automotive industry

Efficiency meets flexibility

Grob is a machine builder with core expertise in the automotive industry. In this success story, you can read how Grob, together with Keba, has succeeded in creating an HMI visualization for the safe operation of its machines and systems during maintenance, service and commissioning work.

Ellenrieder and Gindele are clear about what will happen in the coming years: “The future lies in e-mobility.” © Keba

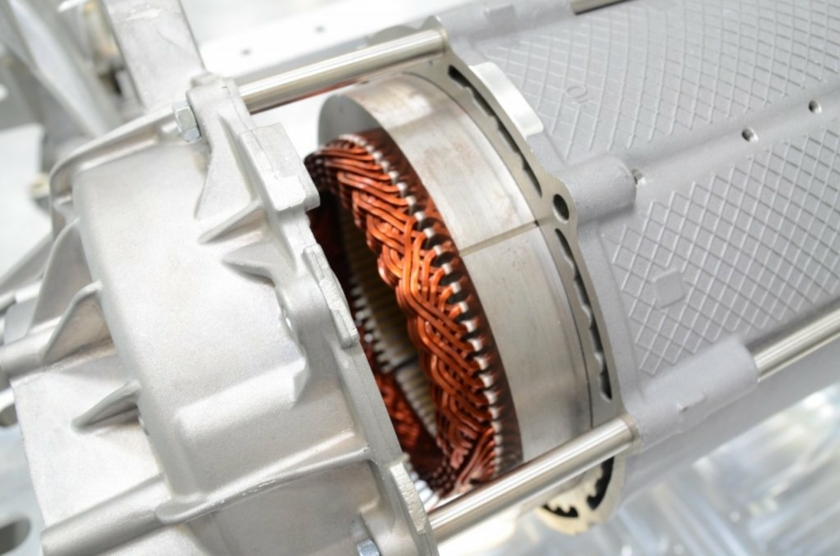

Grob-Werke is primarily active in the fields of universal machines, assembly systems, machining technology and electromobility. © Keba

“The design of the hardware is very positive. It is elegant and appealing – they are durable devices,” says Andreas Gindele. © Keba