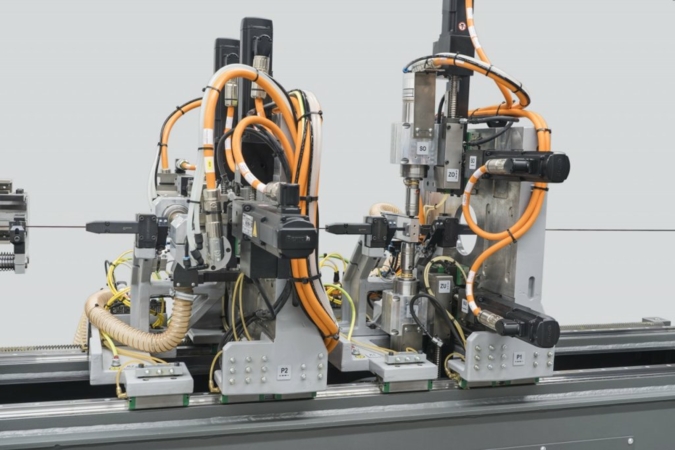

19/09/2022 – CNC transfer bending machine “Speed Former”

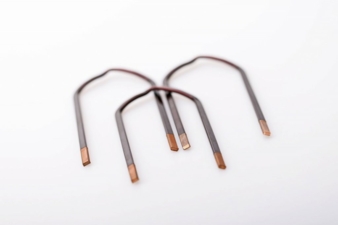

Easy and reliable series production of hairpins

The “Speed Former” made by Wafios is the first machine that unites three well proven bending techniques from conventional wire and tube bending machines in one unique system.