14/11/2023 – The double pressure welding process is used especially in wire drawing shops

Double pressure welding machines

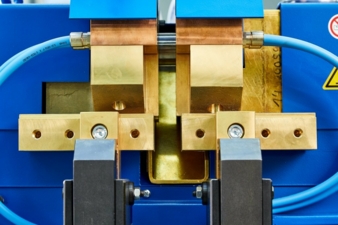

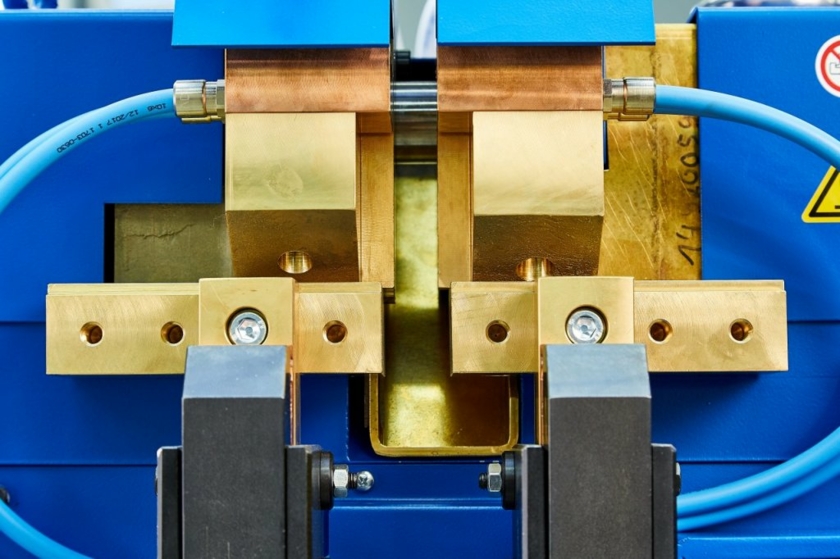

With the double pressure welding machine “DD0 104”, but also the “STS 020” from Ideal-Werk, the heat-affected material made of iron or non-ferrous metal is almost completely pressed out of the welding zone with force after the welding process.

All “DSH” type wire butt welding machines are already equipped with a device for post annealing of low carbon steels as standard. © Ideal-Werk

With the double pressure welding machine “DD0 104” the heat-affected material made of iron or non-ferrous metal is almost completely pressed out of the welding zone with force after the welding process. © Ideal-Werk