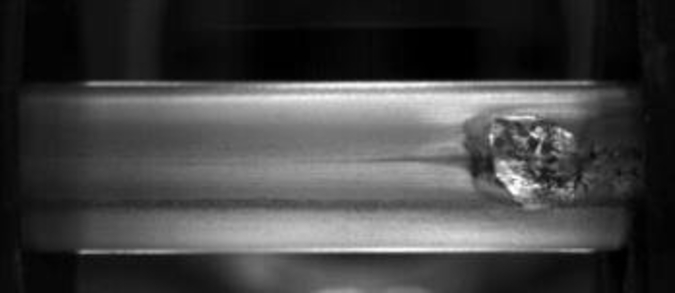

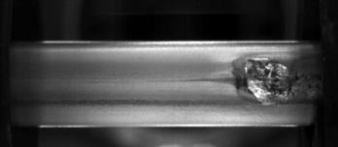

06/06/2022 – High-speed photography

Documentation of quality in wire rolling mills

Electromagnetic testing methods have long been established as a method for quality monitoring in the wire industry. Quick, non-destructive, and reliable, the eddy current method can be used to assess the surface quality of material under test, as well as to monitor the quality of the test results. In many cases, conclusions can be drawn about the production process itself.