30/03/2021 – Wire processing / bending

Bihler: Mechanical engineering at its best

Kostal Kontakt Systeme GmbH is the very first company to use the new processing center “BZ2-S8” from Bihler.

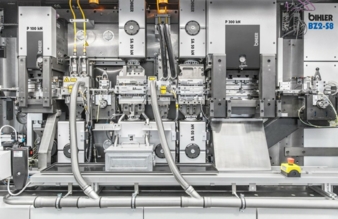

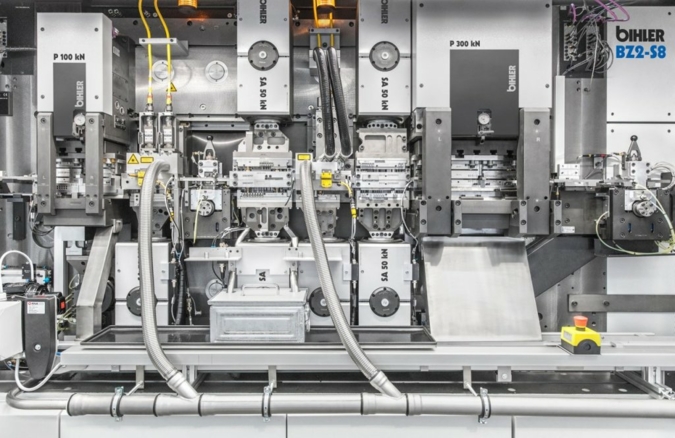

With its central drive units, which are uncoupled from one another, the new “BZ2-S8” operates independently of speed. Thanks to the slide units, it is also possible to use a dual movement approach when manufacturing. © Otto Bihler

For Wolfgang Becker, Head of Production at Kostal Kontakt Systeme, the “BZ2-S8” forms the basis for the high-quality production of contact parts. © Otto Bihler