25/04/2023 – Wire processing / Straightening

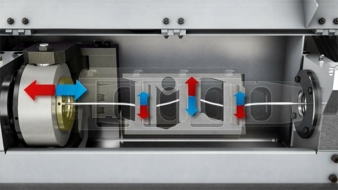

Artificial intelligence optimally adjusts straightening processes

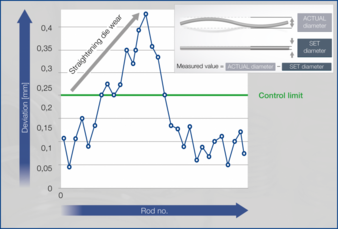

The straightness of the wire is essential for and the starting point of the production of perfect end products. Straightening processes are used in particular when raw materials are wound for economic reasons or the requirements in the downstream process make straightness mandatory.