25/04/2023 – Wire processing / Straightening

Artificial intelligence optimally adjusts straightening processes

The straightness of the wire is essential for and the starting point of the production of perfect end products. Straightening processes are used in particular when raw materials are wound for economic reasons or the requirements in the downstream process make straightness mandatory.

“Roller straightening” and “rotary straightening” are conventional procedures used for straightening wire. At Wafios, both procedures are employed depending on the application. The roller straightening or rotary straightening process are integrated in bending machines that process round wire. For processing flat wire, only the roller straightening process is used due to geometric restrictions. For the production of straightened rods with very high requirements on straightness, different variants of the rotary straightening process are generally used. All straightening processes have in common that they plastically deform the workpiece to eliminate residual stresses in order to achieve the best possible straightness, regardless of the initial product.

Due to complex influencing factors, the straightening process is anything but a trivial process when it comes to achieving best possible straightness. Until now, an operator with many years of experience has been essential to achieve a largely constant straightening result. Wafios has been working for many years on the development of an automated adjustment of the straightening process by means of artificial intelligence methods in order to achieve an optimal straightening process that does not require experienced operators. The approach is that instead of an experienced operator, an artificial intelligence can optimally adjust the straightening processes. In doing so, Wafios uses knowledge gathered over decades and makes this wealth of experience available in a computer-controlled manner using algorithms.

Straightness measurement (iQm-straight) and straightness control (iQstraightcontrol) for rotary straightening

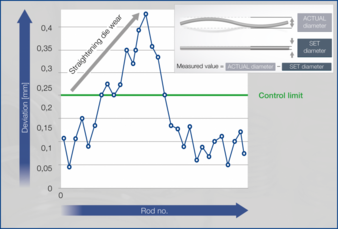

Deviations in the material produced by the previous straightening process, but also the wear of straightening jaws, cause scattering in the straightness of straightened rods. The result is machine downtime, increased rejects and more time spent setting up the machine which leads to increased production costs.

“iQm-straight” enables in-process measurement of straightened rods in order to assess the straightening quality. After the cut, a camera is used to determine the straightness of the rods as they roll down the ejection slope. When exceeding the set limit value, the machine stops automatically and in doing so, the measurement results are logged.

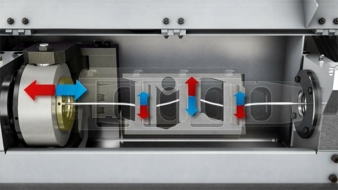

A prerequisite for the automated adjustment of the straightening process without machine downtime is the possibility to advance straightening jaws during the straightening process. This process has been implemented and patented by Wafios using the servomotor-adjustable straightening rotor. Based on the measurement results of “iQm-straight”, “iQstraightcontrol” corrects the position of the straightening jaws fully automatically using the servomotor-adjustable rotor. In this way, the straightening quality can be monitored and readjusted in the process window. The 100% control of the straightened and cut rods and the control of the straightening jaw position is carried out during production without reducing the production speed.

Adaptive straightening (iQsmartstraight) – Partial or fully automated adjustment of the straighteners when roller straightening flat wire

End of last year, Wafios presented the newly developed adaptive straightening function “iQsmartstraight”. An initial application of this process is the straightening of a straight wire for the production of so-called hairpins. Hairpins are insulated copper wires used to manufacture the stator coil of modern electric motors. The use of straight flat wire is necessary for the production of dimensionally accurate hairpins. As a result, the straightening process is one of the key technologies.

With the “iQsmartstraight” function, Wafios has succeeded for the first time in ensuring a fully automatic adjustment of the straighteners, independent of the experience of operators. For this purpose, the fully automated, AI-based straightening management was developed in an internal research project using artificial intelligence, practical experience of more than 125 years in the field of wire processing and extensive simulation calculations.

The developers therefore created a technology that – through the use of artificial intelligence – considers all main influencing factors when straightening wire and incorporates these into the initial setting of the straightening rollers. Subsequent 3D measurements of the straightness of the wire are used to adaptively adjust the feed of the straightening rollers. In this way, when the coil is changed and the corresponding batch fluctuations occur, a good constant straightening result can be achieved without operator influence.

The automatic adaptive straightening system “iQsmartstraight” also robustly adjusts the straightening process like an experienced machine operator. This means that fluctuations in the material properties and the bending of the wire have as little effect as possible on the straightening quality. The revolutionary straightening process reduces set-up times and materials used and thus optimizes not only the adjustment process. The quality of straight rods is improved, the reject rate is reduced. Moreover, the quality of the straightening process is no longer linked to the qualifications of the operator.

Dr.-Ing. Uwe-Peter Weigmann, of the Board of Wafios AG, considers the automation presented in the straightening process as a positive example as to how the application of artificial intelligence can simplify and automate processes that are strongly dependent on the experience of the operator. This form of automation will play an increasingly important role in the future. In times where there are not enough skilled workers available, such technologies are decisive for securing the economic future of a production site. The AI-based straightening process reduces the number of rods required during set-up and reduces rejects in the manufacturing process. This not only increases the economic efficiency of the machine, but also the overall sustainability balance, as the consumption of valuable resources is reduced. For the future, technical modifications will be made to make adaptive straightening processes also available for the processing of round wire.

Interwire 2023, booth 1005

Wafios AG

Silberburgstrasse 5

72764 Reutlingen

Germany

Tel.: +49 7121 146-0

sales@wafios.de

www.wafios.com

Wafios Machinery Corporation

27 NE Industrial Road

Branford, CT 06405, USA

Tel.: +1 203 4815555

service@wafios.us

www.wafios.us