17/05/2022 – Artificial Intelligence (AI) based process assistant

AI based buffering process automation

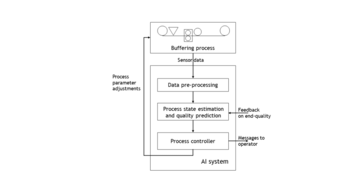

High-speed optical cable manufacturing lines are traditionally controlled using process-automation systems. Maillefer present an Artificial Intelligence (AI) based process assistant, “Smart Buffering”, which operates on top of the process automation layer.

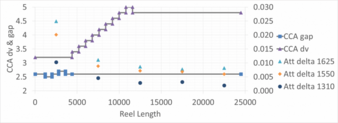

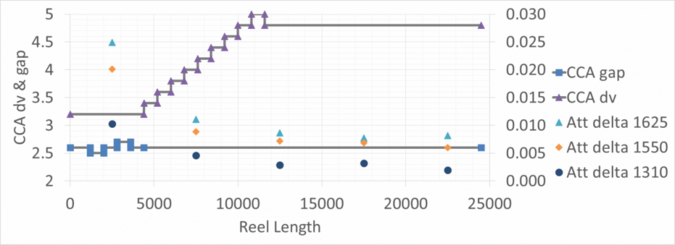

Fig. 3. Smart Buffering system initialization run, with measured attenuation deltas at multiple lengths. © Maillefer

Maillefer present an Artificial Intelligence (AI) based process assistant, “Smart Buffering”, which operates on top of the process automation layer. © Maillefer

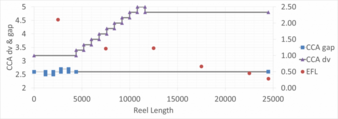

Fig. 1. Smart Buffering forms a control loop to the buffering process, information extracted from line sensor data allows intelligent process parameter adjustments. © Maillefer