17/08/2022 – Great success at Fulgor

RVPP on Catenary lines

After the excellent results achieved with Round Value Package Premium (RVPP/MRC) installed on multiple vertical lines, it was time to offer this technology for catenary lines. A new state of the art high-performance CCV line installed at Fulgor SA, part of Hellenic Cables, provided an ideal start for this technological first.

Long-time customer Fulgor SA of Corinthe, Greece is member of the Cenergy Holdings. They are known for supplying technologically advanced cables as well as for delivering complete turnkey projects, both in the energy and telecom sectors. Submarine cables and its installation are their specialty.

Hellenic Cables recently implemented a 250 Mio. Euro investment plan for production of high- and extra high-voltage submarine cables at Fulgor’s state-of-the-art submarine cable production facility. The recently commissioned high-voltage CCV line contains several novel technological improvements for productivity, reliability, and ease of use.

New solutions for old challenges

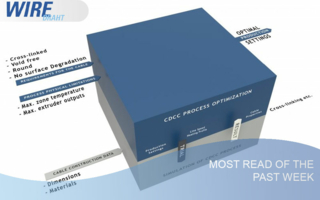

Production of high voltage lines with catenary lines was revolutionized by the widespread adoption of Entry Heat Treatment (EHT) in late 1990’s. EHT enables the production of even the highest voltage range for cables produced on catenary or vertical lines, but at the cost of crosslinking power. With our novel Round Value Package Premium, the production of the same cables is possible without slowing down the line. Controlling the sagging of insulation and roundness via rapid crosslinking, instead privileging insulation cooling, is the key to high productivity.

Maillefer has previously introduced their novel solution for online control of core layer eccentricity known as synchronized “X-Ray” at Fulgor. Naturally, this new line also includes this system. Synchronization is achieved with an X-ray device rotated to match cable orientation at the crosshead. It enables operators interpret a correct orientation of cold x-ray measurements together with hot x-ray ones and allows for extremely easy offset adjustment.

Great value for both parties

When combined, the two technologies described above guarantee excellent core geometry and layer thicknesses for all the way up to the most demanding cable designs. Operators will no longer need to do multiple corrections and comparisons against results of cut samples. The correct offset is displayed from the control room, immediately after start. Commissioning runs confirmed their theories, and the results were once again spectacular. Excellent eccentricity and roundness were reached for the high- and extra high-voltage cables produced with RVPP technology. Production runs were conducted at a considerably high insulation output of 450kg/h, making this line the fastest CCV line producing high voltage submarine cables in the world.

Maillefer Extrusion Oy

Ensimmäinen savu, P.O.Box 176

01511 Vantaa, Finland

Tel.: +358 9 8866 5600

info.finland@maillefer.net

www.maillefer.net