02/12/2020 – For metals, plastics and carbon materials

New hardness tester “Wilson RH2150”

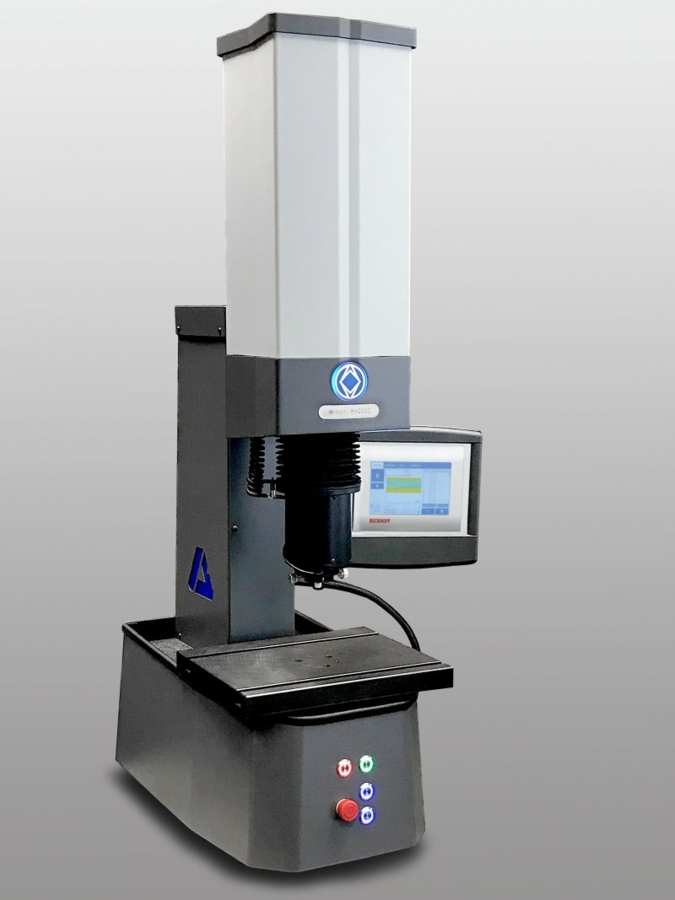

The new “Wilson RH2150” represents the next generation of hardness testers by Buehler – ITW Test+Measurement GmbH, manufacturer of instruments, consumables and accessories for materialography and hardness testing.

With its vast amount of testing scales, the new “Wilson RH2150” hardness tester by Buehler – ITW Test+Measurement is an appropriate solution for a large range of applications in quality control and research environments. © Buehler-ITW