01/07/2021 – Household appliance industry

New halogen-free and new antimony-free FR solutions

New flame retardant masterbatches and compounds from Tosaf are either free of halogens such as bromine and chlorine or – for higher processing temperatures – free of antimony.

What they all have in common is their very good performance combined with high cost efficiency. Typical applications include injection molded parts for household appliances such as refrigerators, washing machines and air conditioners, as well as extrudates such as films and pipes.

Halogen-containing structures can harm the environment and accumulate in living organisms. Therefore, regulations in Europe, the USA and other countries, such as REACH, RoHS and WEEE, have led to the banning of several established flame retardants. The alternative is halogen-free flame retardants (HFFRs), but these often combine higher prices with lower efficacy and stability compared to halogen-containing types.

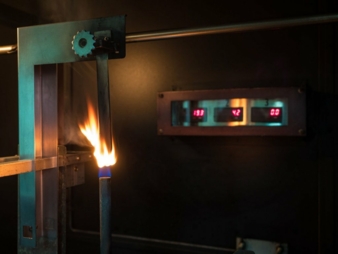

Thanks to its extensive experience and know-how in raw materials and production processes, Tosaf has now been able to develop masterbatches and compounds that offer highly efficient halogen-free flame retardants at a very good price/performance ratio and that are unproblematic to recycle. In FR tests, test specimens produced with these compounds and masterbatches meet stringent requirements in terms of heat release rate, smoke generation and flame spread or burn-through, even at low thicknesses. Tosaf's new HFFR solutions are available for polymers such as ABS, HIPS, PP and PE.

For example, FR7903PP EU is a PP-based compound which produces a ceramic structure in addition to a char layer during firing. It thus meets UL94 5VA requirements at 1.6 mm and, with its low smoke generation and heat release, complies with stringent FR standards including EN13501-1 BS1 do, NFPA 286, ASTM E162, NF P 92 503/507 M1 and LPS 1207. FR2655PE EU is the masterbatch equivalent of the FR7903PP EU compound and is suitable for PP as well as PE.

Most HFFRs for polyolefins and styrenic polymers are not suitable for elevated temperatures. Therefore, for demanding process conditions, halogenated flame retardants with an addition of the synergistic antimony are still in use today. Since this is considered a carcinogenic substance, Tosaf has developed for such applications a range of halogenated antimony-free FR masterbatches and compounds for PE, PP, ABS and HIPS, with FR efficiencies equivalent to conventional antimony-containing grades. For example, the antimony-free FR HIPS compound FR8997PS EU and the corresponding masterbatch FR8669PS EU meet the requirements according to UL94 V-0 at 1.6 mm, UL94 5VA at 2mm, ASTM E162, NF P 92 503/507 M1-2 and LPS 1207.

Tosaf Compounds Ltd.

Tel.: +972 9 8984790

About Tosaf

For over three decades, Tosaf has been developing and manufacturing high quality additives, compounds and color masterbatches for the plastics industry. With the aim of providing for its customers’ every need, it has continuously grown and developed its offering, production capacity, and global reach, becoming a truly close to the market, global organization.

Servicing customers in over 50 countries in Europe, North America, South America, Asia and the Middle East, Tosaf has over 1000 employees spread throughout its production sites, warehouses, sales and distribution offices around the world. Tosaf CEO Amos Megides established the company in Israel in 1986, and still stands at its head, leading and inspiring his team to always uphold the following three pillars: Exceptional service, the highest quality and continuous innovation. Tosaf’s major shareholders include: Megides Holdings Ltd. and the Ravago Group.